Corten Roof Panels A Durable Choice

Corten roof panels offer a striking aesthetic and exceptional durability. These panels, crafted from corten steel, develop a unique, weather-resistant patina over time, adding a distinctive character to any building. The composition and manufacturing process of these panels make them a compelling option for a wide range of architectural styles, from modern to historical restorations.

This exploration delves into the multifaceted aspects of corten steel roofing, including design considerations, installation specifics, cost analysis, and sustainability. We’ll examine their comparative advantages against other roofing materials, showcasing why they stand out in terms of longevity, maintenance, and aesthetic appeal. Furthermore, a detailed look at the installation process, from substrate preparation to fastening and waterproofing, will provide practical insights for prospective users.

Introduction to Corten Steel Roof Panels: Corten Roof Panels

Source: centralsteelservice.com

Corten steel, a unique alloy of steel, boasts a remarkable characteristic: its ability to develop a protective, rust-colored patina over time. This natural process forms a robust and durable surface, rendering the steel resistant to further corrosion. This self-healing property is a key factor in its suitability for outdoor applications, including roofing.

The composition of Corten steel distinguishes it from regular steel. It contains specific elements, primarily copper, chromium, and nickel, which, through a complex electrochemical process, form the distinctive patina. This carefully controlled composition is essential to the steel’s longevity and unique aesthetic. The manufacturing process for Corten steel roof panels typically involves hot rolling the steel into sheets or panels, followed by cold rolling to achieve the desired thickness and finish. Subsequent surface treatments, if required, are applied.

Composition and Manufacturing

Corten steel is a high-strength, low-alloy steel, formulated with a precise mix of elements. This specific chemical composition is what triggers the self-healing oxidation process, creating a protective layer. The addition of copper, chromium, and nickel is crucial in this process. The manufacturing process begins with the careful selection of raw materials, followed by a controlled metallurgical process to achieve the desired alloy. This ensures consistent properties and performance across different batches. The subsequent rolling and shaping processes are critical to attaining the desired form and dimensions of the final roof panel.

Benefits of Corten Steel Roofing

Corten steel roofing offers several advantages over traditional roofing materials. Its inherent corrosion resistance reduces the need for ongoing maintenance, making it a cost-effective solution in the long run. The distinctive rust-colored patina adds a unique aesthetic to the building’s design, providing a visually appealing alternative to more conventional roofing materials. The robustness of Corten steel allows for lighter structural supports, reducing the overall cost and complexity of the roofing system.

Drawbacks of Corten Steel Roofing, Corten roof panels

While Corten steel offers numerous benefits, it also presents some drawbacks. The initial cost of Corten steel roof panels tends to be higher compared to other materials like asphalt shingles. The distinctive patina, while an aesthetic advantage for many, may not be suitable for all architectural styles. The specific color and texture of the patina can vary depending on environmental conditions, potentially affecting the aesthetic consistency of a building.

Comparison to Other Roofing Materials

| Feature | Corten Steel | Asphalt Shingles | Metal Tiles | Concrete Tiles |

|---|---|---|---|---|

| Durability | High | Moderate | High | High |

| Aesthetics | Distinctive patina | Standard | Appealing | Appealing |

| Maintenance | Low | Moderate | Low | Low |

| Cost | High | Low | Moderate | Moderate |

The table above provides a comparative overview of Corten steel roof panels against other common roofing materials, highlighting key differences in durability, aesthetics, maintenance requirements, and cost. This comparison aids in informed decision-making during the selection process for a roofing system.

Design and Application Considerations

Source: dwell.com

Corten steel’s unique aesthetic and durability make it a compelling choice for various architectural projects. Careful consideration of design elements, panel configurations, and load-bearing capacities is crucial for successful installations. Understanding the interplay between these factors ensures the longevity and structural integrity of the roof system.

Designing with Corten steel requires a nuanced approach. Its inherent weathering characteristics, which contribute to its distinctive aesthetic, must be integrated seamlessly into the overall design vision. This includes evaluating how the panel’s color evolution will impact the building’s appearance over time.

Design Considerations for Architectural Styles

Corten steel’s rich, rust-toned patina complements diverse architectural styles. For example, its earthy tones integrate well with contemporary, industrial, and rustic designs. However, its aesthetic can be adapted to suit traditional or historical styles by employing specific panel treatments or color variations. Careful consideration of the building’s existing architectural elements is crucial for achieving a harmonious aesthetic.

Available Shapes, Sizes, and Configurations

Corten steel roof panels are available in a variety of shapes and sizes. Common configurations include rectangular panels, trapezoidal panels, and custom-designed forms. The choice depends on the architectural style, roof pitch, and desired aesthetic. The availability of various panel sizes allows for flexibility in meeting specific project requirements. Custom fabrication options are also available to accommodate complex roof geometries.

Successful Installations in Different Building Types

Numerous successful installations showcase the versatility of Corten steel roof panels. Residential applications often involve sloped roofs, showcasing the material’s beauty in a natural setting. Commercial buildings, such as warehouses or retail spaces, benefit from the material’s durability and visual impact. Industrial structures frequently utilize Corten steel for its strength and resilience. In each instance, the choice of Corten steel reflects the structure’s specific needs and aesthetic vision.

Designing a Corten Steel Roof System

Designing a Corten steel roof system involves meticulous calculations to ensure structural integrity. Engineers must determine the load-bearing capacity of the panels, taking into account factors like snow load, wind pressure, and dead load (weight of the panels). Proper anchoring and support systems are crucial for withstanding anticipated stresses. Critical calculations must be performed by qualified professionals.

Load bearing calculations must adhere to local building codes and safety standards.

Appropriate wind resistance measures must be implemented, including considerations for local wind patterns and potential storm events.

Roof Pitch Suitability

The suitability of Corten steel panels for different roof pitches varies. Steeper pitches offer greater drainage capacity and can accommodate larger panel sizes. Shallower pitches necessitate smaller panels or specialized configurations to ensure adequate water runoff. The following table provides a general guideline:

| Roof Pitch (degrees) | Suitability for Corten Steel Panels |

|---|---|

| 20-30 | Generally suitable, but careful consideration of drainage is needed. |

| 30-45 | Good suitability for most applications. |

| 45-60 | Excellent suitability for large panel sizes and good drainage. |

| >60 | Suitable for specialized applications with appropriate drainage and support systems. |

Installation and Maintenance

Corten steel roof panels, renowned for their durability and aesthetic appeal, demand meticulous installation and ongoing maintenance to ensure longevity and optimal performance. Proper installation procedures and consistent maintenance practices are crucial for preventing leaks, mitigating corrosion, and preserving the structural integrity of the roof system. Addressing potential issues promptly can avoid costly repairs and extend the lifespan of the roof.

Thorough preparation of the substrate and meticulous selection of fastening methods are fundamental to a successful installation. Choosing the right waterproofing and sealing techniques is critical to preventing leaks and maintaining a weather-tight roof.

Substrate Preparation

Careful substrate preparation is paramount for a strong and lasting installation. The existing roof structure must be thoroughly inspected for any damage or irregularities. Any loose or damaged materials must be removed. The surface must be cleaned to eliminate debris, dust, and any contaminants that could compromise the adhesion of the fasteners. Proper surface preparation ensures a secure and durable bond between the substrate and the Corten steel panels.

Fastening Methods

Various fastening systems are suitable for Corten steel roof panels, each with its advantages and considerations. Mechanical fasteners, such as screws or bolts, are common choices. The type of fastener selected depends on the specific substrate, panel design, and wind load requirements. Consideration must be given to the fastener’s corrosion resistance and the panel’s dimensional stability. Properly sized fasteners and appropriate spacing are essential for secure attachment and structural integrity. Adhesive-based systems can also be employed, offering a seamless aesthetic and potentially greater flexibility in complex designs.

Waterproofing and Sealing

A robust waterproofing system is essential to prevent leaks and maintain a weather-tight roof. Effective sealing around panel edges, penetrations, and connections is critical. High-quality sealant, compatible with Corten steel, must be applied according to the manufacturer’s specifications. Careful attention to detail is required during the sealing process. Proper sealing and waterproofing measures are crucial for preventing water damage to the building’s interior and preserving the longevity of the roof structure.

Routine Maintenance

Regular inspections and cleaning are essential to maintain the structural integrity and aesthetic appeal of Corten steel roof panels. Visual inspections should be conducted periodically to detect any signs of corrosion, damage, or loose fasteners. Cleaning the panels should be done using appropriate cleaning agents to remove dirt and debris without harming the panels’ protective patina. Routine maintenance helps to prolong the life of the panels and minimize the need for extensive repairs.

Addressing Potential Issues

Corrosion and panel damage are potential issues that require prompt attention. Identifying corrosion early can prevent further damage and structural failure. If corrosion is observed, appropriate treatment methods should be implemented to address the issue. Panel damage may require replacement. The correct assessment and resolution of these issues are crucial to maintaining the roof’s integrity and functionality.

Replacing a Damaged Panel

Replacing a damaged Corten steel roof panel involves several steps. First, carefully assess the damage and determine the extent of the required replacement. Disassembly of the damaged panel and surrounding panels may be required to safely access the damaged section. Once the damaged panel is removed, the substrate should be cleaned and inspected for any underlying damage. A new, compatible panel should be installed using appropriate fasteners and sealing techniques. Careful adherence to manufacturer guidelines is crucial for successful replacement.

Cost and Sustainability

Corten steel roof panels, known for their aesthetic appeal and durability, present a compelling alternative to traditional roofing materials. However, a comprehensive evaluation must consider the full cost spectrum, encompassing material, installation, and long-term maintenance. Understanding the environmental impact alongside the financial implications is crucial for a well-rounded assessment of their overall viability.

A careful comparison of Corten steel’s cost against other roofing options, along with a life-cycle cost analysis, reveals valuable insights into its economic feasibility. Further, understanding the environmental footprint of Corten steel, from sourcing to manufacturing to disposal, is essential for evaluating its sustainability credentials. The longevity of Corten steel roofing, coupled with its reduced replacement frequency, highlights its long-term sustainability benefits.

Cost Comparison with Other Roofing Materials

Different roofing materials vary significantly in their initial cost. Factors like material availability, labor rates, and local regulations all influence the final price. A comparative analysis, considering these factors, is essential to determine the overall economic viability of Corten steel.

| Roofing Material | Approximate Cost (per square meter) | Notes |

|---|---|---|

| Corten Steel | $XXX – $YYY | Prices fluctuate based on location, panel size, and installation complexity. |

| Asphalt Shingles | $ZZZ – $XXX | A common, relatively affordable option, but with a shorter lifespan. |

| Metal Roofing (Aluminum, Steel) | $PPP – $QQQ | Often comparable to Corten steel in cost, but may vary based on material thickness and features. |

| Tile Roofing | $RRR – $SSS | A higher-end option, known for its aesthetic appeal and durability. |

*Note: The table above provides a general comparison. Specific pricing should be verified with local suppliers and installers. The exact cost figures (XXX, YYY, ZZZ, etc.) are examples and will vary significantly based on the factors mentioned above.*

Life Cycle Cost Analysis

Evaluating the life cycle cost of Corten steel roofing involves assessing various factors over its entire lifespan. This encompasses the initial material cost, installation expenses, and projected maintenance requirements. The long-term cost savings from reduced replacement needs are significant factors to consider.

- Material Costs: Corten steel, while initially more expensive than some alternatives, often demonstrates a lower overall cost over time due to its extended lifespan. The higher upfront cost is often offset by reduced future replacements and maintenance.

- Installation Costs: Installation costs for Corten steel roofing can vary depending on project complexity, labor rates, and the use of specialized equipment. Careful planning and a detailed installation process are key to minimizing potential cost overruns.

- Maintenance Costs: Corten steel’s inherent durability and corrosion resistance often minimize maintenance needs. Regular inspections and occasional cleaning can significantly reduce potential future costs. The passive nature of its weathering process is a key aspect of its reduced maintenance.

Environmental Impact

The environmental impact of Corten steel roofing extends from material sourcing to manufacturing and eventual disposal. Factors such as the steel’s origin, energy consumption during manufacturing, and the material’s recyclability are all crucial aspects to evaluate.

- Material Sourcing: The environmental footprint of Corten steel is influenced by the origin of the raw materials used in its production. Sustainable sourcing practices and responsible supply chains can mitigate potential environmental concerns.

- Manufacturing Processes: The energy consumption and emissions generated during the manufacturing process significantly impact Corten steel’s environmental profile. Optimizing manufacturing processes and utilizing renewable energy sources can reduce the environmental footprint.

- Disposal and Recycling: Corten steel is highly recyclable, making it a sustainable choice from an end-of-life perspective. Proper disposal and recycling procedures ensure minimal environmental impact.

Sustainability Benefits

Corten steel’s inherent durability contributes significantly to its sustainability profile. The extended lifespan of the roofing system translates into a reduced need for replacements and associated environmental impacts. Furthermore, the recyclability of the material offers an additional layer of sustainability.

- Longevity: The inherent corrosion resistance and durability of Corten steel result in a significantly longer lifespan compared to many other roofing materials. This extended lifespan reduces the frequency of replacements, thereby minimizing the environmental impact associated with manufacturing new roofing materials.

- Reduced Replacements: The longevity of Corten steel roofing reduces the need for frequent replacements. This translates into fewer manufacturing processes, less material extraction, and lower transportation emissions, ultimately leading to a more sustainable practice.

- Recyclability: Corten steel is fully recyclable. This aspect of the material allows for the efficient reuse of the metal, reducing the need for extracting new raw materials, which significantly benefits the environment.

Aesthetic and Architectural Applications

Corten steel’s unique aesthetic qualities make it a compelling choice for architectural design. Its ability to develop a distinctive patina over time, coupled with its inherent strength and durability, offers architects and designers a range of possibilities for creating visually striking and enduring structures. This section explores the various applications of Corten steel roof panels, highlighting their aesthetic impact and versatility.

Corten steel’s distinctive patina is a key element of its aesthetic appeal. The natural weathering process transforms the initially bright-orange-red hue of the steel into a rich, warm brown or grey, depending on the specific environmental conditions and the type of steel. This gradual transformation, which is both predictable and unpredictable, creates a dynamic and visually captivating effect. This inherent aging process adds a layer of character and depth to any structure.

Patina Development and Color Variations

The development of the Corten steel patina is a complex process influenced by factors such as the composition of the steel, the local climate, and the amount of exposure to the elements. The initial rust-like coloration is followed by the formation of a protective layer of iron oxides that ultimately stabilizes the steel’s surface. This layer protects the underlying metal from further corrosion while maintaining the distinctive aesthetic appeal. The resulting color variations offer design flexibility. For instance, a roof panel might develop a rich brown hue in a coastal environment, while a similar panel in a drier, more arid climate might transition to a muted grey.

Architectural Design Enhancement

Corten steel roof panels can significantly enhance the architectural design of a building. Their robust and textured appearance complements various architectural styles, ranging from modern minimalist designs to more traditional or historical restorations. The deep, rich color of the aged patina can act as a focal point or as a subtle counterpoint to other elements of the building’s design. The panels’ ability to create visual interest can make a statement in any design.

Examples of Architectural Styles

- Contemporary Buildings: Corten steel panels can create a bold and modern aesthetic. Their weathered appearance, combined with the clean lines of contemporary architecture, results in a sophisticated, enduring look. The patina adds depth to the structure while maintaining a sleek modern form.

- Industrial Buildings: The raw, industrial aesthetic of Corten steel panels is perfectly suited for buildings with a similar aesthetic. The inherent robustness and weathering resistance of Corten steel make it an ideal choice for exposed structures and industrial settings.

- Historical Restorations: In historical restoration projects, Corten steel can be used to create a seamless blend between old and new. Its weathering properties allow it to age in a manner that complements the existing structure, offering a harmonious integration. The patina’s development mirrors the aging of the building’s other materials, providing a cohesive and aesthetically pleasing result.

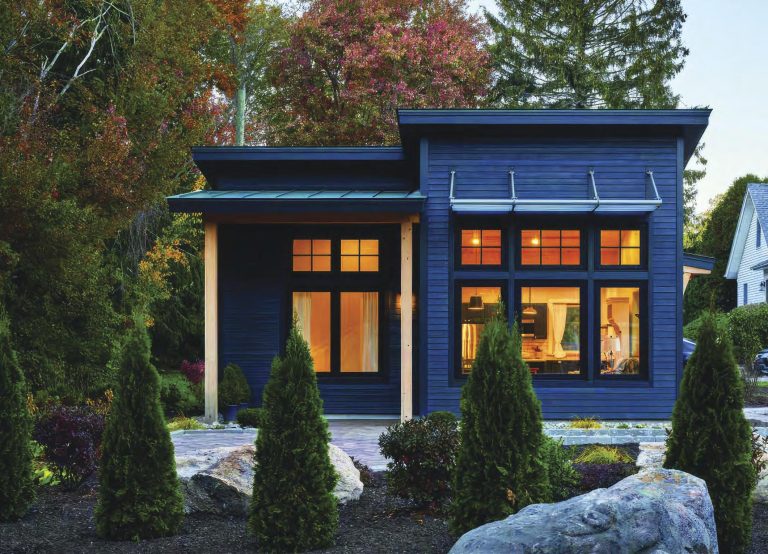

- Residential Homes: Corten steel roof panels can be incorporated into residential designs to create a visually engaging roofline. Their ability to complement the natural elements of a landscape and blend seamlessly with other building materials makes them ideal for residential applications.

Versatility in Diverse Settings

Corten steel’s adaptability extends to a wide range of architectural settings. From grand public structures to smaller residential homes, its versatility allows for a wide array of design choices. The material’s inherent durability and longevity make it a suitable choice for structures requiring long-term aesthetic appeal and structural integrity. Furthermore, the color variations that arise during the weathering process allow for a customized and personalized aesthetic.

Utilizing Color Variations for Design Statements

The range of color variations in the Corten steel patina allows architects to create distinct design statements. By strategically placing panels with different stages of weathering, architects can create a visual narrative that emphasizes the building’s character and history. This variability in color and texture offers possibilities for nuanced design expressions, transforming a structure into a dynamic and evolving piece of architecture.

Concluding Remarks

In conclusion, corten roof panels present a compelling blend of durability, aesthetics, and sustainability. Their unique properties, coupled with careful design and installation, ensure long-lasting performance and a distinctive architectural statement. While the initial cost might be higher compared to some alternatives, the long-term benefits and low maintenance requirements ultimately justify the investment, making them an appealing choice for both residential and commercial projects. This detailed overview provides a comprehensive understanding of the various facets of corten steel roofing, equipping you with the knowledge to make informed decisions about your roofing needs.