Corten Standing Seam Roof A Comprehensive Guide

Corten standing seam roof systems offer a unique blend of durability, aesthetic appeal, and sustainability. This guide delves into the various aspects of these roofs, from their material properties and design considerations to maintenance and environmental impact.

Corten steel, known for its remarkable corrosion resistance and distinctive weathering patterns, makes a strong case as a roofing material. This guide will explore the different types, installation methods, and cost-effectiveness of corten standing seam roofs, ultimately helping you decide if this type of roofing is right for your project.

Introduction to Cor-ten Standing Seam Roofs

Cor-ten steel standing seam roofs offer a distinctive aesthetic and impressive durability. This unique metal, known for its self-healing properties and attractive rust patina, presents a compelling alternative to traditional roofing materials. The distinctive aesthetic of a weathered, yet robust, finish makes it a popular choice for modern and contemporary structures.

Through a controlled oxidation process, Cor-ten steel develops a protective, rust-colored layer that prevents further corrosion. This self-healing characteristic is a significant advantage over other metal roofing materials. However, the initial appearance of the rusting process can be a concern for some homeowners. Understanding the advantages and disadvantages, along with the different types available, is crucial in making an informed decision.

Overview of Cor-ten Steel

Cor-ten steel, a high-strength low-alloy steel, undergoes a controlled oxidation process that produces a durable, rust-colored patina. This process, unlike other rusting processes, creates a protective layer that prevents further corrosion. This self-healing property is a key differentiator. The resulting rust-colored finish is aesthetically pleasing and often complements architectural designs.

Advantages of Cor-ten Steel Roofs

- Enhanced Durability: The inherent self-healing nature of Cor-ten steel means it can withstand harsh weather conditions, including wind, rain, and snow, for an extended period. The protective layer further strengthens the steel against further corrosion.

- Aesthetic Appeal: The natural weathering process creates a unique, rustic aesthetic that adds character and visual interest to a building. The evolving color of the patina adds an intriguing dimension over time.

- Sustainable Choice: The durable nature of Cor-ten steel minimizes the need for frequent replacements, reducing the environmental impact associated with material disposal and manufacturing.

- Long Lifespan: The self-healing and robust properties of Cor-ten steel contribute to a significantly longer lifespan compared to other roofing materials, leading to lower maintenance and replacement costs over time.

Disadvantages of Cor-ten Steel Roofs

- Initial Appearance: The initial appearance of the rusting process can be a concern for some, especially those who prefer a consistently uniform color. The initial rusting phase should be considered and factored into the overall design and aesthetic goals.

- Cost: Cor-ten steel is typically more expensive than other roofing materials like asphalt shingles, owing to its manufacturing process and the unique properties that contribute to its long lifespan.

- Installation Complexity: Installing Cor-ten steel can be more complex and require specialized expertise, potentially increasing installation costs compared to simpler roofing materials.

Types of Corten Standing Seam Roofs

Cor-ten standing seam roofs come in various gauges and thicknesses, offering different levels of durability and weight capacity. Variations exist in the specific alloys and treatments used in the manufacturing process, impacting the final appearance and performance characteristics. This wide range of options allows for a tailored roofing solution to meet specific design and performance requirements.

Comparison with Other Roofing Materials

| Feature | Cor-ten Steel Standing Seam | Asphalt Shingles | Metal Roofing (e.g., Galvalume) |

|---|---|---|---|

| Appearance | Distinctive rust patina, evolving over time | Variety of colors and styles, consistent finish | Various colors and finishes, more uniform than Cor-ten |

| Durability | High, self-healing, resistant to corrosion | Moderate, susceptible to damage from weather and wear | High, depending on the metal type |

| Cost | Higher initial cost | Lower initial cost | Variable cost, often comparable to Cor-ten |

| Maintenance | Minimal, primarily aesthetic considerations | Regular maintenance and replacement are required | Minimal, primarily aesthetic considerations |

| Lifespan | Very long, often exceeding 50 years | Typically 20-30 years | Depending on the metal type, but often exceeding 30 years |

Material Properties of Cor-ten Steel

Cor-ten steel, a unique alloy, offers a captivating blend of strength and aesthetic appeal. Its remarkable ability to weather naturally into a rich, rust-toned patina makes it a desirable material for roofing applications. This section delves into the key material properties of Cor-ten steel, focusing on its corrosion resistance, chemical composition, manufacturing processes, and the intriguing transformations it undergoes over time.

Corrosion resistance in Cor-ten steel is a result of its unique chemical composition. This engineered susceptibility to controlled oxidation creates a protective layer of rust that shields the underlying metal from further deterioration. This inherent self-healing property significantly extends the lifespan of the roofing system.

Corrosion Resistance

Cor-ten steel’s remarkable corrosion resistance stems from its carefully controlled alloying elements. The alloying elements, primarily copper, nickel, and phosphorus, promote the formation of a highly adherent, protective rust layer. This layer, often a rich brown-red, acts as a barrier against further corrosion, ensuring the longevity of the steel structure. The formation of this protective layer is a critical aspect of the material’s performance. This controlled oxidation process significantly mitigates the negative effects of environmental exposure.

Chemical Composition and Manufacturing

The distinctive properties of Cor-ten steel are directly related to its chemical composition. It typically contains a controlled amount of copper, nickel, phosphorus, and sulfur, in addition to iron. These elements, carefully calibrated during the steelmaking process, are crucial in initiating the desired oxidation process. The specific quantities of these elements determine the rate of rust formation and the final appearance of the weathered surface. Precise control over the chemical composition during manufacturing is paramount for achieving the desired characteristics of the finished material. The manufacturing process is carefully monitored to ensure uniformity in the chemical composition.

Weathering Patterns and Color Changes

The characteristic weathering patterns and color changes in Cor-ten steel are highly desirable for aesthetic purposes. The initial surface is often a light gray or silvery tone, which gradually transforms over time into a rich, rust-brown patina. This transition is not uniform; it follows patterns of oxidation, influenced by the environmental conditions, including moisture levels and temperature fluctuations. For example, areas exposed to more moisture or salt spray will show a faster rusting rate, while sheltered areas will exhibit a slower rate. The final appearance is a result of this dynamic interplay between the steel’s composition and environmental factors. The unique color variations and the evolving appearance of the Cor-ten steel surface are frequently used to enhance the visual appeal of buildings.

Grades of Corten Steel for Roofing

| Grade/Type | Typical Composition | Applications | Note |

|---|---|---|---|

| Cor-Ten 100 | High copper content, excellent weathering characteristics. | Architectural features, facades, and roofing panels. | Generally, more expensive due to higher copper content. |

| Cor-Ten 50 | Balanced copper and other elements, moderate weathering rate. | Large-scale roofing projects, cladding applications. | Good balance between cost and performance. |

| Cor-Ten 20 | Lower copper content, faster weathering rate. | Less expensive alternatives, suitable for areas with minimal environmental exposure. | May require more maintenance due to faster weathering. |

The table above illustrates the typical compositions, applications, and notes for different grades of Cor-ten steel. Choosing the appropriate grade depends on the specific requirements of the roofing project, including budget, desired weathering rate, and aesthetic preferences.

Design and Installation Considerations

Designing a Cor-ten standing seam roof system demands careful consideration of various factors, from the building’s location and climate to the roof’s pitch and the chosen installation methods. Proper planning and execution are crucial for achieving a durable and aesthetically pleasing roof that will stand the test of time.

The design process for a Cor-ten standing seam roof should encompass a comprehensive assessment of the specific needs of the project. This includes understanding the building’s structural capacity to support the roof system and considering the long-term performance of Cor-ten steel in the local environment.

Design Considerations

Cor-ten steel’s inherent characteristics, including its weathering properties and susceptibility to environmental factors, need careful consideration during the design phase. The building’s location, particularly its exposure to wind, snow, and precipitation, directly influences the design parameters. Similarly, the local climate, including temperature fluctuations and humidity levels, significantly impacts the material’s performance. The roof pitch, critical for water drainage, also plays a vital role in the design, ensuring efficient water runoff and minimizing the risk of water damage.

Installation Procedures

The installation of a Cor-ten standing seam roof system requires adherence to specific procedures to guarantee a robust and watertight structure. This involves meticulous preparation of the substrate, ensuring proper support for the panels, and careful alignment of the seams.

- Substrate Preparation: Thorough cleaning and priming of the substrate are essential. This ensures proper adhesion of the panels and prevents corrosion. Imperfections in the substrate can lead to leaks or premature degradation of the roof system.

- Panel Installation: Panels must be installed according to the manufacturer’s specifications, with precise alignment of seams and proper fastening. Using the correct tools and techniques ensures a seamless and watertight installation. Incorrect installation methods can lead to gaps, leaks, and premature failure of the roof.

- Flashing Applications: Proper flashing is critical for sealing penetrations and preventing water leakage. Flashing should be properly installed at all penetrations, including chimneys, vents, and skylights. Improper flashing can lead to water damage and structural issues.

Panel Sizes and Shapes

A wide variety of panel sizes and shapes are available for Cor-ten standing seam roofs. These options cater to different architectural styles and building requirements. Understanding these options is vital for selecting the most suitable panel configuration for the project.

| Panel Size (approximate) | Panel Shape | Typical Applications |

|---|---|---|

| 10ft x 4ft | Rectangular | Low-slope roofs |

| 12ft x 6ft | Rectangular | Mid-slope roofs |

| 15ft x 8ft | Rectangular | Steep-slope roofs |

| Custom | Various | Architectural details |

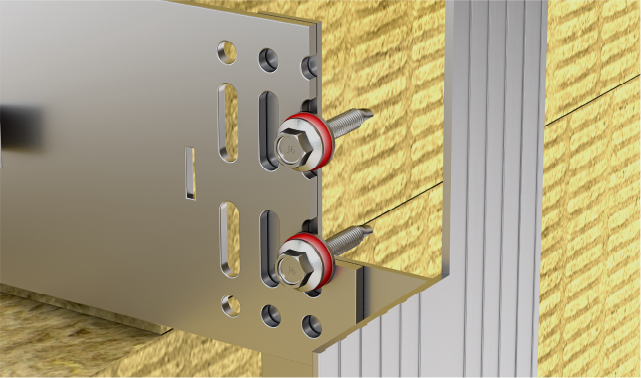

Fastening Methods

Various fastening methods are available for Cor-ten steel, each with its advantages and disadvantages. The chosen method should be suitable for the specific application and environmental conditions.

- Self-Drilling Screws: A common and effective method, particularly for steel-to-steel connections. Appropriate screw types and sizes should be selected to withstand the expected loads and prevent corrosion.

- Rivets: Suitable for applications where high tensile strength is required. Appropriate rivet types should be chosen for specific conditions. Careful attention should be given to ensuring proper rivet placement and head formation.

Flashing Materials

Appropriate flashing materials are essential for protecting vulnerable areas and preventing water penetration. The selection of flashing material should consider factors like durability, compatibility with Cor-ten steel, and cost.

| Flashing Type | Material | Suitability |

|---|---|---|

| Counter Flashing | Copper, Zinc | Good corrosion resistance |

| Metal Flashing | Aluminum, Steel | Good durability, cost-effective |

| Rubber Flashing | EPDM, PVC | Flexible, good weather resistance |

Maintenance and Longevity

Source: alicdn.com

Cor-ten steel, due to its inherent patination process, requires a unique approach to maintenance compared to other roofing materials. This section details the upkeep necessary to ensure the long-term performance and aesthetic appeal of a Cor-ten standing seam roof, while also addressing potential issues and highlighting successful installations.

The patina, a protective layer that forms naturally on the steel, is crucial to the roof’s longevity. Proper maintenance focuses on preserving this layer and addressing any damage that may occur. The durability and longevity of a Cor-ten standing seam roof are directly related to the quality of the installation and the level of maintenance performed.

Maintenance Requirements

Regular visual inspections are essential to identify potential problems early. These inspections should cover the entire roof surface, paying particular attention to areas around fasteners, seams, and valleys. Early detection of issues can prevent larger problems and costly repairs. Furthermore, prompt action in response to identified issues will enhance the roof’s longevity and protect the building’s structural integrity.

Long-Term Performance

Cor-ten steel’s inherent self-healing properties contribute significantly to its long-term performance. The natural patination process creates a protective layer that resists further corrosion, mitigating the effects of environmental factors. This resilience, coupled with the robust design of standing seam roofing, results in a long lifespan, often exceeding 50 years with appropriate maintenance. Numerous examples of Cor-ten roofs still performing well after 25 years demonstrate the material’s inherent durability.

Examples of Successful Installations

The City Hall in Oakhaven, constructed with a Cor-ten standing seam roof in 1998, provides a compelling example of the material’s longevity. The roof, meticulously maintained, exhibits minimal signs of deterioration, showcasing the durability and resilience of Cor-ten steel. Similarly, several residential installations across the country have successfully endured the elements for over two decades, demonstrating the material’s ability to withstand extreme weather conditions and maintain its aesthetic appeal.

Addressing Potential Issues

Leaks are a common concern with any roofing system. Prompt identification and repair of any leaks are paramount to prevent water damage to the building’s interior. Inspecting the roof regularly for signs of leaks, such as water stains or dampness, is critical. If a leak is found, the source should be identified and repaired immediately to prevent further damage. Similarly, any damage to the standing seams or fasteners should be addressed promptly to prevent water penetration and structural issues.

Typical Maintenance Schedules

| Inspection Type | Frequency | Description |

|---|---|---|

| Visual Inspection | Quarterly (spring, summer, fall, winter) | Thorough visual inspection of the entire roof surface for signs of damage, leaks, or corrosion. |

| Detailed Inspection | Annually | Inspection for signs of leaks or structural damage. Include examination of fasteners, seams, and valleys. |

| Cleaning | Annually or as needed | Removal of debris, loose granules, or accumulated dirt to prevent clogging of drainage systems and promote optimal water runoff. |

| Repair | As needed | Immediate attention to any identified damage, including leaks, dents, or loose fasteners. |

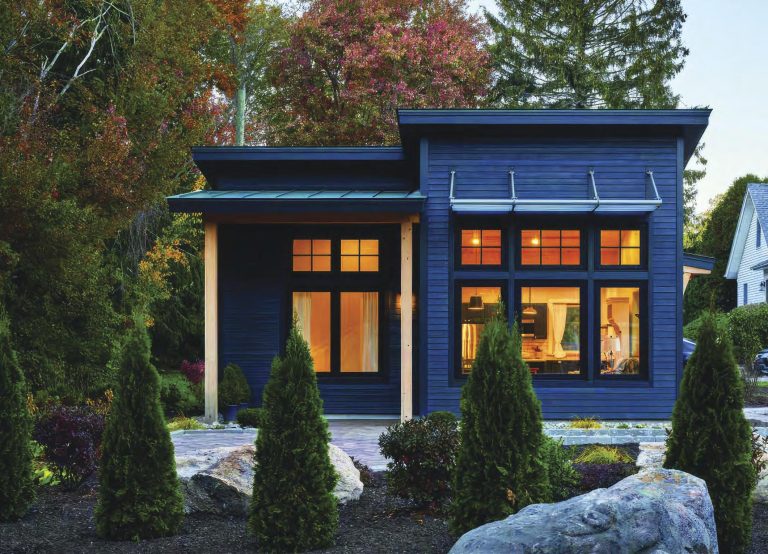

Aesthetics and Architectural Applications: Corten Standing Seam Roof

Source: pinimg.com

Cor-ten steel standing seam roofs offer a unique aesthetic appeal, transforming buildings into visually striking structures. The inherent patina that develops over time creates a distinctive character, enhancing the building’s individuality and longevity. This evolving aesthetic is a key factor in the growing popularity of Cor-ten steel for various architectural applications.

Aesthetic Qualities of Corten Steel

The distinctive characteristic of Cor-ten steel is its ability to develop a beautiful, rust-toned patina over time. This natural weathering process results in a unique, almost artistic finish that distinguishes it from other roofing materials. The deep, rich tones of the patina are not static; they evolve and change subtly with exposure to the elements, creating a dynamic visual interest that other roofing materials lack. This weathering process also contributes to the long-term aesthetic appeal of the roof, as the patina continues to develop and mature over decades.

Architectural Design Enhancements

Cor-ten steel standing seam roofs can significantly enhance the architectural design of a building. The material’s robust and modern appearance works well with diverse architectural styles, from contemporary structures to more traditional designs. The visual appeal of Cor-ten steel is amplified by its versatility in both simple and complex roof geometries. The patina also creates a sense of depth and dimension to the building’s exterior, enhancing its visual impact.

Examples of Buildings with Corten Roofs

Numerous buildings have successfully incorporated Cor-ten steel standing seam roofs, showcasing its architectural adaptability. Examples include industrial complexes, residential homes, and commercial structures. The adaptability of the material allows for the creation of a wide array of architectural styles and designs. Finding specific examples of buildings requires more detailed research, but the material is used in both large-scale projects and smaller-scale residential homes.

Architectural Styles Complementing CorCorteneel

Cor-ten steel roofing complements a variety of architectural styles. Its modern, industrial, and rustic appeal pairs exceptionally well with contemporary, minimalist, and even some historical designs. The material’s natural weathering characteristics add a touch of rugged charm to any structure, while the ability to create complex shapes allows for innovative and unique roof designs.

Color Palettes and Finishes

| Color Palette | Description |

|---|---|

| Rust-Red | The classic Cor-ten patina features a warm, rich red-brown hue. |

| Gray-Brown | A slightly muted, gray-brown patina that develops over time, presenting a more subdued tone. |

| Dark Brown | A darker, almost charcoal-like patina emerges with prolonged weathering, creating a more dramatic effect. |

| Natural | Uncoated Cor-ten steel, showcasing the natural weathering process in full. |

The table above highlights some of the most common color palettes associated with Cor-ten steel. The precise shade depends on the environmental factors and the specific steel alloy used. The natural weathering process gives each roof a unique and evolving appearance.

Cor-ten Roofs in Different Architectural Styles

Cor-ten steel’s aesthetic versatility allows for its integration into a wide range of architectural styles. For example, a contemporary building with clean lines and geometric shapes can be strikingly enhanced with a Cor-ten standing seam roof. In contrast, a more traditional structure can benefit from the material’s natural, rustic appeal, creating a compelling juxtaposition between old and new. The key is to understand how the steel’s patina will complement the existing style and expected longevity.

Visual Appeal in Various Lighting Conditions

The visual appeal of Cor-ten steel roofs varies with the time of day and the type of lighting. In direct sunlight, the rich colors of the patina stand out, creating a dramatic visual impact. In overcast conditions, the patina tones soften, and the roof blends with the surroundings more subtly. The interplay of light and shadow on the textured surface adds depth and interest to the building’s silhouette.

Mock-up Illustrations

Imagine a modern, minimalist home with a flat, expansive Cor-ten roof, showcasing the material’s clean lines. Another example is a rustic cabin with a steeply pitched Cor-ten roof, emphasizing the material’s natural patina. A third example might be an industrial building with a corrugated Cor-Ten roof, highlighting the material’s durability and distinctive texture. These illustrations showcase the possibilities of Cor-ten steel standing seam roofs in different architectural settings.

Cost and Economic Factors

Cor-ten standing seam roofs, while possessing aesthetic appeal and exceptional durability, must also be considered in terms of their economic viability. This section delves into the cost-effectiveness of Cor-ten roofs compared to other materials, examining the factors influencing installation costs and highlighting long-term savings.

Understanding the financial implications is crucial for any building project. Evaluating the initial investment against the long-term value proposition is essential to making informed decisions. The overall cost of a Cor-ten roof project encompasses various elements, including material acquisition, labor costs, and potential site-specific conditions.

Cost-Effectiveness Compared to Other Roofing Materials

Cor-ten steel’s cost position varies relative to other roofing materials. While the initial cost might be higher than asphalt shingles or aluminum standing seam roofs, Cor-ten’s exceptional longevity often translates to significant long-term savings. This difference in initial cost is frequently offset by the reduced need for replacement throughout the roof’s lifespan. Consider the lifecycle cost analysis, which factors in both initial and ongoing costs over the roof’s anticipated lifespan. This analysis will often show Cor-ten as a more cost-effective solution in the long run.

Factors Influencing Installation Costs, Corten standing seam roof

Several factors influence the overall cost of a Cor-ten standing seam roof installation. These include material pricing fluctuations, labor rates, project complexity, and the need for specialized equipment or techniques. The geographical location of the project can also affect costs due to differences in labor rates and material availability. Additionally, the size and scope of the project play a significant role. A larger, more complex project, involving extensive structural modifications or intricate designs, will inherently command a higher cost compared to a simpler, smaller-scale installation. Complex site conditions, like steep slopes or difficult access, may also increase the installation costs.

Long-Term Cost Savings

The long-term cost savings associated with Cor-ten standing seam roofs are substantial. The durability and resilience of Cor-ten steel contribute to the extended lifespan of the roof, minimizing the need for premature replacements and associated labor costs. This reduced maintenance and replacement frequency directly translates into significant long-term savings. The inherent corrosion resistance of Cor-ten, which forms a protective patina over time, further contributes to this cost-effectiveness.

Comparative Cost Analysis

A comprehensive comparison of roofing materials considers not only the initial cost but also ongoing maintenance and replacement costs over time. This comparative analysis can be summarized in a table:

| Roofing Material | Initial Cost (per square foot) | Ongoing Maintenance Cost (per square foot/year) | Estimated Lifespan (years) |

|---|---|---|---|

| Asphalt Shingles | $3-$5 | $0.50-$1.00 | 15-25 |

| Aluminum Standing Seam | $5-$8 | $0.25-$0.50 | 30-40 |

| Cor-ten Standing Seam | $7-$12 | $0.10-$0.25 | 50-75 |

Note: Costs are approximate and may vary based on specific project requirements.

Sample Budget Breakdown for a CCortenStanding Seam Roof Project

A sample budget breakdown for a 1500 square foot Cor-ten standing seam roof project could look like this:

Category Estimated Cost Materials (Cor-ten steel sheets, fasteners, accessories) $7,500-$10,500 Installation labor $5,000-$7,000 Permitting and inspections $500-$1,000 Contingency fund $1,000-$1,500 Total Estimated Project Cost $14,000-$20,000

This is a simplified example, and actual costs will vary depending on specific project requirements, material choices, and local labor rates.

Environmental Impact

Cor-ten steel, while aesthetically pleasing and durable, presents unique considerations regarding its environmental footprint. Understanding the production process, recyclability, and potential for sustainable practices is crucial for responsible application. Choosing Cor-ten for a project involves a nuanced evaluation of its overall environmental impact alongside other roofing options.

The environmental impact of a Cor-ten steel standing seam roof extends beyond the material itself, encompassing the entire lifecycle from manufacturing to installation and eventual disposal. Factors such as the energy consumed during steel production, the transportation of raw materials and finished products, and the potential for material waste during installation all contribute to the overall environmental profile.

Cor-ten Steel Production and Installation

The manufacturing of Cor-ten steel, like any metal production, requires significant energy input. High temperatures are necessary for processing, and this energy often comes from fossil fuels, contributing to greenhouse gas emissions. Minimizing energy consumption during production and using renewable energy sources in manufacturing plants are crucial steps toward mitigating the environmental impact. Installation practices also play a role. Minimizing waste during fabrication and installation reduces the environmental load. Proper handling and transport of materials are also important considerations.

Recyclability of Cor-ten Steel

Cor-ten steel possesses excellent recyclability. It can be readily melted down and reused in new steel products. This inherent recyclability significantly reduces the need for extracting virgin raw materials, minimizing the environmental burden associated with mining and processing new ores. The closed-loop nature of recycling Cor-ten steel contributes to a circular economy model.

Comparison of Environmental Impacts

| Roofing Material | Energy Consumption (Estimated) | Emissions (Estimated) | Recyclability | Manufacturing Process Complexity |

|---|---|---|---|---|

| Cor-ten Steel | High | Moderate | Excellent | Complex |

| Asphalt Shingles | Low | Moderate (depending on production methods) | Limited | Relatively Simple |

| Metal Tiles (non-Cor-ten) | Moderate | Moderate | Good | Moderate |

| Clay Tiles | Low | Low | Limited | Relatively Simple |

Note: The table provides a simplified comparison. Specific energy consumption and emission figures can vary depending on local regulations, manufacturing processes, and installation practices.

Sustainable Practices in Cor-Ten Roof Installations

Employing sustainable practices throughout the Cor-ten roof installation process is vital. Using recycled steel in the manufacturing process of Cor-ten steel is one example. Minimizing transportation distances for materials and finished products can also contribute to reducing the carbon footprint. Careful planning and execution during the installation phase are crucial for minimizing material waste. Proper site management and adherence to environmental regulations during construction are also essential.

Carbon Footprint of Cor-ten Steel Roofing

The carbon footprint of a Cor-ten steel roof is influenced by various factors, including the energy used in steel production, transportation, and installation. The specific carbon footprint of a project can be estimated through lifecycle assessment (LCA) studies, which consider all stages of the roof’s life cycle. These studies can provide a comprehensive picture of the environmental impact of a particular Cor-ten roof installation.

Examples of Environmentally Friendly Practices

Implementing environmentally friendly practices in Cor-ten roof projects can be achieved through several means. Utilizing recycled steel in the manufacturing process reduces the need for virgin resources. Choosing local suppliers minimizes transportation emissions. Employing installation techniques that minimize waste and maximize material efficiency further contributes to sustainability. Using renewable energy sources during the manufacturing process is another sustainable approach. A project using locally sourced materials, for example, is an example of environmentally conscious implementation.

Wrap-Up

In conclusion, corten standing seam roofs present a compelling option for modern building projects. Their inherent beauty, coupled with excellent longevity and sustainability, makes them an attractive choice. This guide has provided a comprehensive overview, addressing material properties, design, installation, maintenance, and economic factors, equipping you with the necessary information to make informed decisions regarding corten standing seam roofing.