Metal Cladding Companies A Comprehensive Guide

Metal cladding companies play a crucial role in modern construction, transforming buildings with durable and aesthetically pleasing exteriors. From the initial design concepts to the final installation and maintenance, these companies manage every aspect of a cladding project. Understanding the different types of metal used, the diverse applications, and the crucial services offered is key to making informed decisions when selecting a company.

This comprehensive guide explores the various facets of metal cladding companies, covering everything from the different types of metals employed to the key factors influencing the choice of a company. We’ll examine market trends, case studies, geographical distribution, and crucial client considerations, providing a well-rounded perspective for anyone involved in or considering a metal cladding project.

Introduction to Metal Cladding Companies

Metal cladding, a crucial element in modern construction, involves the application of thin sheets of metal to the exterior surfaces of buildings. This method enhances aesthetics, protects against the elements, and contributes significantly to the overall structure’s longevity. The choice of metal cladding impacts both the visual appeal and the structural performance of a building.

Metal cladding systems offer diverse advantages, from enhanced durability and weather resistance to unique aesthetic possibilities. The careful selection of metal type and application method directly influences the final appearance and lifespan of a building. Different metal types exhibit unique properties, influencing their suitability for specific applications.

Types of Metal Used in Cladding

Various metals are employed in cladding applications, each with distinct characteristics. Steel, aluminum, and copper are prevalent choices, each offering a specific balance of properties. Steel, for example, provides high strength and durability, while aluminum boasts excellent lightweight properties and corrosion resistance. Copper, renowned for its aesthetic appeal and inherent resistance to corrosion, is a favored choice for its longevity and distinctive patina.

Applications of Metal Cladding in Construction

Metal cladding finds widespread use in various architectural projects. It’s frequently employed in commercial buildings, residential structures, and even industrial facilities. The applications extend beyond simple aesthetic enhancement, as metal cladding can offer significant structural benefits, including improved fire resistance and sound insulation. Modern buildings often integrate metal cladding to create distinctive architectural features, enhancing both the building’s appearance and its overall performance.

Examples of Buildings Using Metal Cladding

Numerous notable structures showcase the versatility of metal cladding. The iconic Hearst Tower in New York City, for instance, exemplifies the use of stainless steel cladding, showcasing the material’s ability to create a sophisticated and durable facade. Likewise, the Sydney Opera House, with its unique copper-clad design, demonstrates the potential of metal cladding to produce striking and enduring architectural statements.

Material Type, Application, and Aesthetic Considerations

| Material Type | Application | Aesthetic Considerations |

|---|---|---|

| Steel | High-rise buildings, industrial structures | Strength, durability, varied finishes (e.g., painted, brushed, stainless steel) |

| Aluminum | Residential homes, commercial spaces, and curtain walls | Lightweight, corrosion-resistant, diverse color options, and reflectivity |

| Copper | Historical buildings, contemporary designs, and roofing | Distinctive patina, longevity, warm aesthetic, sustainability (recyclable) |

| Stainless Steel | Commercial buildings, high-end residential, and exterior facades | Durability, corrosion resistance, sleek aesthetic, reflectivity |

The table above summarizes the various applications and aesthetic considerations associated with different metal cladding types. Choosing the right material is crucial for ensuring a structure’s long-term performance and visual appeal.

Services Offered by Metal Cladding Companies

Source: com.au

Metal cladding companies play a crucial role in the construction industry, providing expertise in the design, fabrication, and installation of metal cladding systems. These systems enhance building aesthetics, improve energy efficiency, and provide long-term protection against the elements. Understanding the comprehensive services offered by these companies is essential for clients seeking high-quality, durable, and aesthetically pleasing exterior finishes.

Core Services

Metal cladding companies typically offer a range of services encompassing the entire project lifecycle, from initial consultation to post-installation maintenance. Their core services include design, fabrication, and installation, ensuring a seamless and effective project execution. These services are integrated to guarantee a cohesive and durable final product.

Pre-Construction Processes

Thorough pre-construction processes are essential for the successful execution of any metal cladding project. These processes involve detailed site surveys to assess the building’s structural characteristics and environmental conditions. Material selection is a crucial step, considering factors such as weather resistance, aesthetic requirements, and budget constraints. Moreover, obtaining necessary design approvals and permits is vital to ensure compliance with building codes and regulations. This includes detailed coordination with architects and engineers to guarantee the project aligns with the building’s overall design and functionality.

Fabrication and Installation Procedures

Fabrication procedures involve meticulous preparation and processing of the metal cladding materials. This includes cutting, shaping, and welding the metal components according to the approved design specifications. Installation procedures involve the secure and precise mounting of the fabricated metal panels onto the building’s exterior structure. This often requires specialized equipment and skilled labor to ensure accurate alignment and adherence to the project specifications. Adherence to safety protocols during fabrication and installation is paramount.

Post-Installation Maintenance Strategies

Proper maintenance strategies are crucial for preserving the longevity and aesthetic appeal of metal cladding. Regular inspections are essential to identify any signs of damage or deterioration, such as corrosion or loose panels. Addressing these issues promptly minimizes the risk of structural damage or aesthetic degradation. Furthermore, preventative measures like cleaning and repainting, when necessary, will extend the lifespan of the cladding system. A proactive maintenance plan will contribute to the longevity of the structure and the integrity of the cladding.

Project Stages

| Stage | Description |

|---|---|

| Initial Consultation | Meeting with the client to understand project requirements, budget, and aesthetic preferences. Discussion of design options and material selection. |

| Design and Planning | Development of detailed design drawings, including specifications for materials, dimensions, and installation methods. Obtaining necessary approvals and permits. |

| Material Procurement | Acquisition of high-quality metal cladding materials according to the approved specifications. Ensuring the materials meet industry standards. |

| Fabrication | Precision cutting, shaping, and assembling of metal components in a controlled environment. Quality control checks at each stage. |

| Installation | Secure and precise mounting of the fabricated metal panels onto the building’s exterior. Compliance with safety regulations and project specifications. |

| Quality Assurance | Thorough inspection of the completed installation to ensure compliance with the project specifications. Identification and resolution of any issues. |

| Post-Installation Maintenance | Ongoing maintenance to ensure the longevity and aesthetic appeal of the cladding. Regular inspections and preventative measures to address any issues. |

Factors Affecting the Choice of a Metal Cladding Company

Selecting the right metal cladding company is crucial for a successful project. Factors like experience, project management, quality control, and pricing models all play a vital role in ensuring the final product meets expectations and the project stays on schedule and within budget. A well-informed decision will contribute to a long-lasting and aesthetically pleasing outcome.

Experience and Expertise in Metal Cladding

A company’s experience and expertise directly impact the quality and efficiency of the cladding work. Established companies with a proven track record in similar projects often demonstrate a deeper understanding of complex technical challenges and have refined processes for handling diverse materials and specifications. They also typically have a more extensive network of skilled workers, contributing to quicker project completion. For example, a company with decades of experience in high-rise building cladding is likely to handle the intricacies of wind load calculations and material tolerances more effectively than a newer firm.

Project Management Capabilities

Strong project management is essential for any cladding project, ensuring the project stays on track and within budget. Companies with efficient project managers can effectively coordinate all aspects of the job, from material procurement and installation to scheduling and communication. A clear project timeline and the ability to adapt to unforeseen circumstances are key indicators of sound project management. This includes proactive communication, timely updates, and a clear understanding of the client’s needs.

Quality Control Procedures

Rigorous quality control procedures are paramount in metal cladding projects. These procedures, implemented from the design phase to the final installation, guarantee the integrity and longevity of the cladding. This includes strict adherence to specifications, regular inspections, and detailed documentation of the entire process. A well-defined quality control plan often involves pre-installation checks, during-installation monitoring, and post-installation evaluations to detect and address any potential defects or deviations from the agreed standards.

Comparison of Pricing Models

Metal cladding companies utilize various pricing models, reflecting the complexity and scale of the project. Some companies offer fixed-price contracts, providing certainty regarding the total cost. Others employ a cost-plus model, where costs are determined based on materials and labor. Value-engineered proposals, based on cost-effective solutions without compromising quality, are also a viable option. A thorough understanding of the pricing model is essential for accurate budgeting and cost management.

Essential Criteria for Selecting a Metal Cladding Company

Choosing the right company involves careful consideration of several factors. The following table presents essential criteria and corresponding weightings, enabling a more informed decision-making process.

| Criteria | Weighting (0-100%) |

|---|---|

| Experience and Expertise | 30% |

| Project Management Capabilities | 25% |

| Quality Control Procedures | 20% |

| Pricing Models and Transparency | 15% |

| Client References and Reviews | 10% |

Market Trends and Future Outlook: Metal Cladding Companies

The metal cladding industry is experiencing dynamic shifts, driven by evolving design aesthetics, sustainability concerns, and technological advancements. This evolution presents both opportunities and challenges for companies in the sector. From innovative material choices to stringent regulatory frameworks, understanding these trends is crucial for staying competitive and adaptable.

The demand for metal cladding continues to rise, particularly in high-rise buildings and urban infrastructure projects. This increase is fueled by the desire for aesthetically pleasing facades, durable structures, and the potential for energy efficiency gains through the use of advanced cladding systems.

Current Market Trends

The metal cladding market is currently characterized by a strong emphasis on aesthetics and performance. Architects are increasingly incorporating intricate designs and customized finishes, demanding cladding solutions that can meet these complex requirements. Furthermore, the focus on sustainability and reduced environmental impact is driving the adoption of recycled materials and low-emission manufacturing processes.

Emerging Technologies and Materials

Several emerging technologies and materials are reshaping the metal cladding landscape. Advanced coatings are being developed to enhance corrosion resistance and improve the lifespan of cladding systems. Smart materials, capable of adapting to changing environmental conditions, are also gaining traction. Lightweight, high-strength alloys, such as aluminum-lithium composites, are becoming increasingly popular for their aesthetic appeal and reduced structural load. Additionally, the use of prefabricated cladding panels is streamlining construction processes, enabling faster installation and reduced on-site labor costs.

Sustainability Considerations and Environmentally Friendly Practices

Sustainability is a paramount concern in the metal cladding industry. Companies are increasingly adopting environmentally friendly practices, such as using recycled materials, minimizing waste during manufacturing, and utilizing sustainable transportation methods. The selection of materials with low embodied carbon is also a key consideration. The growing demand for LEED-certified buildings and other sustainability standards is further driving this trend. For example, the use of recycled aluminum in cladding systems significantly reduces the carbon footprint compared to virgin materials.

Role of Regulations and Standards

Government regulations and industry standards play a crucial role in shaping the metal cladding industry. These regulations address safety, performance, and environmental impact. Compliance with building codes and industry standards is essential for ensuring the safety and durability of cladding systems. For instance, stringent fire resistance standards are mandated for cladding in high-rise buildings to prevent the spread of fire.

Comparison of Metal Cladding Materials (Environmental Impact Focus)

| Material | Pros (Environmental Impact) | Cons (Environmental Impact) |

|---|---|---|

| Recycled Aluminum | Low embodied carbon, readily recyclable, reduces reliance on virgin resources. | Manufacturing process can still have an environmental impact, and sourcing recycled material can be challenging in some regions. |

| Stainless Steel | High corrosion resistance, long lifespan, durable, and can be recycled. | Higher embodied carbon compared to aluminum, the manufacturing process can be energy-intensive. |

| Copper | Naturally antimicrobial, recyclable, aesthetically pleasing, and relatively low embodied carbon. | Higher cost than other materials, and susceptibility to oxidation. |

| Zinc | Excellent corrosion resistance, readily recyclable, and can be coated for enhanced aesthetics. | The manufacturing process can have some environmental impact, and requires proper disposal and recycling infrastructure. |

Choosing a material requires a holistic assessment, considering the specific project requirements, environmental impact, and long-term costs. A company’s commitment to sustainable practices and adherence to regulations is also a significant factor.

Case Studies of Metal Cladding Projects

Source: marketresearchfuture.com

Metal cladding, a vital element in modern architectural design, presents numerous opportunities for innovation and aesthetic expression. Real-world projects showcase the diverse applications and potential benefits of this material. These case studies delve into successful implementations, highlighting the challenges faced and the solutions employed, as well as the long-term performance of different cladding systems.

Examining completed projects offers valuable insights into the practical application of metal cladding, including the technical and aesthetic considerations. Analyzing successful implementations can help prospective clients anticipate and address potential issues, ultimately leading to more informed decisions.

Successful Metal Cladding Projects: A Detailed Look

Various metal cladding projects have demonstrated impressive results in terms of aesthetic appeal, durability, and performance. These projects serve as valuable examples for architects, engineers, and clients considering metal cladding for their structures.

Aesthetic Impact of Different Metal Cladding Styles

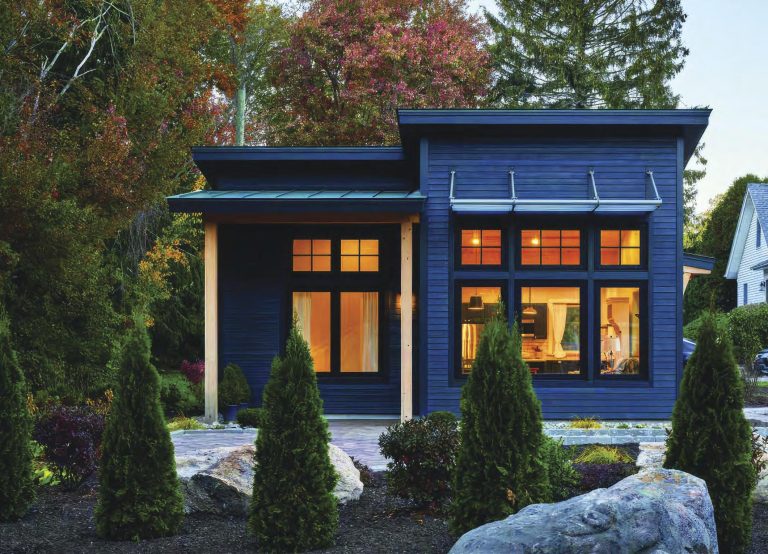

The aesthetic impact of metal cladding is a significant factor in building design. Different styles of metal cladding can drastically alter the appearance of a building. For instance, a smooth, reflective aluminum facade conveys a modern, sleek image, while a corrugated steel cladding provides a more industrial or rustic aesthetic. Careful consideration of the building’s context and the desired aesthetic is crucial for selecting the appropriate cladding style.

Challenges and Solutions in Metal Cladding Projects

Metal cladding projects, while often impressive, can present various challenges. These challenges can range from material selection and procurement to on-site installation and project management. Addressing these challenges effectively is key to a successful project. One critical aspect is ensuring the chosen material aligns with the building’s structural requirements and environmental conditions. Adequate planning and meticulous execution are vital for achieving the desired outcome.

Long-Term Performance and Durability of Metal Cladding Systems

The long-term performance and durability of metal cladding systems are essential factors for any building. Different metal types and finishes exhibit varying degrees of resistance to weathering, corrosion, and environmental stresses. This requires careful consideration of the specific climate and environmental conditions when selecting a cladding system. Regular maintenance and appropriate protective coatings can significantly enhance the lifespan and aesthetic appeal of the cladding.

Table of Case Studies

| Project Name | Location | Material Used | Key Project Features |

|---|---|---|---|

| The Modern Metropolis | New York City, USA | Aluminum composite panels, various colors | Sleek, contemporary design; high reflectivity; excellent resistance to weathering. |

| The Industrial Hub | Chicago, USA | Corrugated steel panels, pre-coated | Durable, robust design; cost-effective; aesthetic suitability for industrial environments. |

| The Sustainable Spire | London, UK | Stainless steel panels, specialized finish | Eco-friendly design, high corrosion resistance, exceptional durability, and sustainable design features. |

| The Coastal Haven | Miami, USA | Zinc panels, textured finish | High corrosion resistance, naturally beautiful aging effect, harmonious integration with the coastal environment. |

Geographic Distribution of Metal Cladding Companies

Metal cladding companies are not uniformly distributed across the globe. Factors like local building codes, construction practices, and the presence of specialized materials influence their concentration in certain regions. Understanding this distribution is crucial for clients seeking metal cladding services, as it impacts project timelines, costs, and the availability of specific expertise.

Major Regions with High Concentration

The North American market, particularly the United States and Canada, demonstrates a significant concentration of metal cladding companies. This is often attributed to the robust construction sector and the high demand for metal cladding solutions in various architectural projects. Europe, especially countries like Germany, the UK, and France, also boasts a strong presence of metal cladding companies, reflecting the region’s emphasis on high-quality construction and architectural design. Asia, specifically regions like China and Japan, is experiencing a rapid growth in metal cladding companies, driven by burgeoning infrastructure development and urbanization.

Availability of Specialized Metal Cladding Services

The availability of specialized metal cladding services varies significantly across regions. North America, for example, has a broad range of providers offering various types of metal cladding, including aluminum, copper, and stainless steel, with expertise in complex architectural designs. In contrast, certain developing regions may have limited access to advanced metal cladding techniques or specific material types. European companies often specialize in high-performance, sustainable metal cladding systems, while Asian companies may focus on cost-effective solutions for large-scale projects.

Comparison of Average Project Costs and Service Availability

The following table provides a general comparison of average project costs and service availability in different regions. Note that these figures are estimates and can vary depending on specific project requirements and material choices.

| Region | Average Project Cost (USD) | Service Availability (Scale of 1-5, 5 being highest) | Specialized Services (Examples) |

|---|---|---|---|

| North America | $150,000 – $500,000+ | 4 | Aluminum, copper, stainless steel cladding; complex architectural designs; advanced fireproofing |

| Europe | $120,000 – $400,000+ | 4 | High-performance, sustainable metal cladding systems; advanced coatings; specialized architectural metalwork |

| Asia | $80,000 – $300,000+ | 3 | Cost-effective solutions for large-scale projects, galvanized steel cladding, and various metal finishes |

| South America | $70,000 – $250,000+ | 2 | Limited access to advanced metal cladding techniques, localized material sources, and traditional metalwork |

Illustrative Map of Metal Cladding Company Distribution

A map showing the geographic distribution of metal cladding companies would depict clusters in North America, Europe, and Asia. High concentrations would be shown in major urban areas known for extensive construction activity, such as metropolitan regions in the USA, Europe, and East Asia. The map would also indicate the relative density of providers in each region. The map would be an effective visual aid for identifying potential partners in various geographic locations.

Key Considerations for Clients Choosing Metal Cladding

Selecting the right metal cladding company is crucial for a successful project. Careful consideration of budgeting, timelines, communication, and quality assurance is paramount to achieving the desired outcome. Thorough planning and due diligence during the selection process can mitigate potential risks and ensure a positive project experience.

Budgeting and Cost Analysis, Metal cladding companies

Accurate budgeting and cost analysis are vital for any metal cladding project. This involves not just the initial material costs but also factoring in labor, transportation, permits, and potential unforeseen expenses. Detailed cost breakdowns, including material specifications, labor rates, and project contingency funds, should be articulated in the proposal. A comprehensive cost analysis allows clients to make informed decisions and avoid costly surprises down the line. For example, a detailed breakdown of material costs, considering different metal types and finishes, is essential to accurately estimate the overall budget. Comparing quotes from multiple vendors is also crucial to ensure competitive pricing and avoid overspending.

Project Timelines and Scheduling

Effective project timelines and scheduling are essential for maintaining a smooth workflow and completing the project within the agreed-upon timeframe. This involves a clear understanding of the project’s phases, from initial design to final installation. A well-defined schedule with realistic deadlines for each stage ensures the project stays on track. This schedule should incorporate contingency time for potential delays, such as weather-related issues or material sourcing challenges. Project timelines should be articulated in the contract to minimize misunderstandings and ensure timely completion.

Communication and Collaboration

Open communication and effective collaboration between the client and the metal cladding company are critical for a successful project. Regular communication channels, such as scheduled meetings, progress reports, and direct contact, should be established to ensure everyone is informed and on the same page. Active listening, clear articulation of needs, and prompt responses to inquiries are all vital components of a strong working relationship. Establishing clear communication protocols, including response times and preferred methods of communication, is beneficial.

Evaluating the Quality of Work

Evaluating the quality of work performed by a metal cladding company is essential to ensure the project meets the client’s expectations. This involves inspecting the cladding materials, installation techniques, and adherence to design specifications. Inspection should include verification of material compliance with standards, adherence to the contract, and overall aesthetic appeal. Regular site visits and inspections by the client or a designated representative throughout the project will help ensure quality control. Using pre-defined quality control checklists and documenting findings are vital for a transparent process. Examples of quality control procedures include rigorous visual inspections, adherence to safety protocols, and testing for structural integrity.

Key Questions to Ask Potential Metal Cladding Companies

| Category | Question |

|---|---|

| Budget & Cost | What is your detailed breakdown of costs, including materials, labor, and permits? |

| Timeline & Scheduling | What is your proposed project timeline, including key milestones and potential delays? |

| Communication & Collaboration | How will you ensure regular communication and collaboration throughout the project? |

| Quality & Experience | Can you provide references and case studies of similar projects? |

| Insurance & Guarantees | What are your insurance coverages and guarantees for the work performed? |

| Warranty & Maintenance | What warranty do you offer, and what is the maintenance process after the project is complete? |

Final Summary

In conclusion, navigating the world of metal cladding companies requires a thorough understanding of their services, expertise, and market trends. Choosing the right company involves careful consideration of experience, project management, quality control, and pricing models. By considering factors such as geographical availability, budgeting, and communication, clients can ensure a successful and satisfying project outcome. The future of metal cladding looks promising, driven by innovation and sustainability concerns. This guide has equipped you with the knowledge to make informed decisions in this exciting field.