Metal Cladding Contractors A Comprehensive Guide

Metal cladding contractors play a crucial role in modern construction, transforming buildings with durable and aesthetically pleasing exteriors. This guide dives deep into the world of metal cladding, exploring various materials, installation techniques, and contractor selection strategies. Understanding these facets is vital for both building owners and prospective clients looking to enhance their projects.

From selecting the right metal cladding material to evaluating contractor qualifications and managing project timelines, this guide provides a comprehensive overview. We’ll cover everything from the initial design phase to final inspection, ensuring a smooth and successful project. A thorough understanding of the process is critical for achieving the desired outcome, and this guide aims to equip readers with the necessary knowledge.

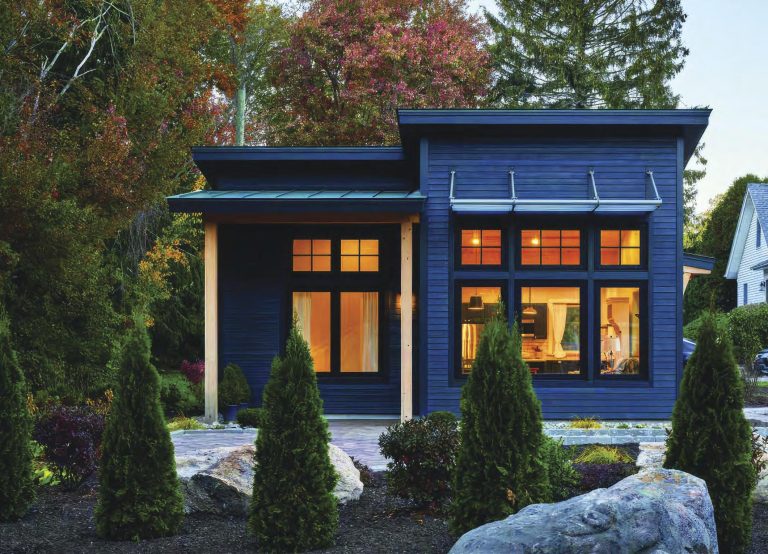

Metal Cladding Services

Source: anryhome.com

Metal cladding, a vital component in modern construction, significantly enhances a building’s aesthetic appeal and structural integrity. This process involves the application of exterior metal sheets or panels to a building’s facade. A skilled metal cladding contractor ensures the longevity and performance of the cladding system, considering factors like weather resistance, fire safety, and energy efficiency.

The selection of appropriate metal cladding materials, installation methods, and adherence to local regulations are critical for successful and enduring results. This comprehensive overview delves into the various aspects of metal cladding services, providing detailed information about materials, installation techniques, project examples, cost analysis, and regulatory considerations.

Metal Cladding Materials

Different metal cladding materials offer distinct properties, influencing their suitability for various architectural projects. Understanding these characteristics is crucial for making informed decisions.

- Aluminum Cladding: Known for its lightweight nature, excellent corrosion resistance, and wide range of finishes. Its affordability and ease of fabrication make it a popular choice for many applications. However, it may not be as strong as some other materials, and its performance can be affected by severe weather conditions.

- Copper Cladding: Renowned for its natural aging process, creating a unique patina over time. This provides an aesthetically pleasing finish and excellent durability. However, copper cladding can be more expensive and requires specific maintenance considerations.

- Steel Cladding: A robust and versatile option with high tensile strength. Various coatings and finishes enhance its corrosion resistance, making it suitable for diverse building types. Steel cladding’s strength comes at a higher price point compared to aluminum.

- Zinc Cladding: Known for its exceptional corrosion resistance, often used in areas with harsh climates. It provides a long lifespan and a unique aesthetic. Zinc cladding might be a costlier option than aluminum, but it’s a durable choice for long-term protection.

Installation Methods and Techniques, Metal cladding contractors

Proper installation is critical for the longevity and performance of metal cladding. Adherence to established techniques and safety protocols is essential.

- Fastening Systems: The chosen fasteners are critical to the structural integrity of the cladding. Different fasteners are appropriate for various materials and thicknesses. Choosing the correct fasteners is vital for the long-term structural stability of the cladding system.

- Seaming Techniques: Proper seaming ensures watertightness and a smooth, aesthetic finish. Different seaming methods are employed based on the specific metal and the desired aesthetic. A skilled contractor will use appropriate seaming techniques to ensure a watertight and aesthetically pleasing cladding system.

- Safety Precautions: Working at heights necessitates strict adherence to safety protocols. Scaffolding, fall protection equipment, and appropriate training are essential to prevent accidents. Safety is paramount during the installation process, and all workers must follow strict safety procedures.

Successful Project Examples

Numerous successful projects demonstrate the versatility of metal cladding across various architectural styles and building types.

- Modern High-Rise: Aluminum cladding is frequently used on modern high-rises, offering a sleek aesthetic and durability in a high-wind environment.

- Historic Restoration: Copper cladding is a common choice for historic restoration projects, harmonizing with the existing architectural style and offering lasting protection.

- Commercial Buildings: Steel cladding is commonly employed in commercial buildings, offering strength, durability, and a variety of design options.

Cost-Effectiveness Comparison

The cost-effectiveness of different metal cladding materials and installation methods varies based on several factors.

| Material | Installation Method | Estimated Cost (per square meter) | Advantages | Disadvantages |

|---|---|---|---|---|

| Aluminum | Fastening | $50-$100 | Affordable, Lightweight | Susceptible to dents and scratches |

| Copper | Seaming | $150-$250 | Aesthetic, Durable | Higher initial cost, potential for patina variations |

| Steel | Fastening/Welding | $75-$150 | Strong, Versatile | Higher maintenance requirements |

| Zinc | Seaming/Fastening | $80-$120 | Excellent corrosion resistance | Slightly higher cost than aluminum |

Permits and Regulations

Local regulations and permits are essential for metal cladding projects.

| Region | Permits Required | Building Codes | Specific Regulations |

|---|---|---|---|

| USA | Building permit, fire code approval | IBC (International Building Code) | Vary by state and local jurisdiction |

| Europe | Building permit, fire safety certificate | EN standards | Vary by country and region |

| Australia | Building permit, council approval | BCA (Building Code of Australia) | Vary by state and territory |

Contractor Selection and Evaluation

Choosing the right metal cladding contractor is crucial for a successful project. A poorly selected contractor can lead to costly delays, quality issues, and even safety hazards. Thorough evaluation is key to ensuring the project meets specifications and adheres to budget and timeline constraints.

Careful consideration of various factors, from experience and certifications to pricing models and contractual agreements, is essential for a positive outcome. Understanding the contractor’s capabilities and approach is vital for minimizing potential risks and maximizing the value of the investment.

Essential Factors for Contractor Selection

Selecting a metal cladding contractor requires careful consideration of several key factors. Experience demonstrates a contractor’s ability to handle complex projects, while certifications ensure adherence to industry standards. Insurance protects both the contractor and the client in case of unforeseen circumstances. A robust portfolio showcases past projects, providing insight into the contractor’s capabilities and quality of work.

Contractor Evaluation Checklist

Evaluating potential contractors involves a multifaceted approach. Assess their technical expertise, considering their knowledge of metal cladding materials, techniques, and industry best practices. Evaluate their project management skills, including their ability to manage timelines, budgets, and communication effectively. Customer reviews offer valuable insights into the contractor’s reputation and past performance. This evaluation should include inquiries about the contractor’s safety protocols and procedures.

Pricing Models and Hidden Costs

Metal cladding contractors often use different pricing models, including fixed-price contracts, cost-plus contracts, and time-and-materials contracts. Fixed-price contracts offer a clear and predictable budget, but potential hidden costs may arise if unforeseen complications arise during the project. Cost-plus contracts allocate costs based on actual expenses, which can be beneficial for projects with uncertain scopes. Time-and-materials contracts, which are based on time and material costs, can lead to unpredictable final costs if the project exceeds the estimated timeframe. Thorough cost breakdowns and detailed specifications are essential to avoid surprises and hidden costs.

Contractual Agreements

A well-defined contract is paramount for a successful project. It should articulate the scope of work, project timelines, and payment terms. A detailed scope of work helps to avoid misunderstandings and ensures that all aspects of the project are clearly defined. Specific timelines provide a framework for progress and prevent delays. Payment terms should be explicit and transparent, ensuring that both parties are aware of their obligations and responsibilities.

Dispute Resolution Procedures

Disputes or disagreements with a metal cladding contractor should be addressed promptly and professionally. Establish clear communication channels and conflict resolution mechanisms within the contract. Mediation or arbitration can be utilized to resolve disputes amicably and cost-effectively. A well-defined escalation process ensures a structured approach to resolving issues.

Typical Roles and Responsibilities of a Metal Cladding Contractor

| Role | Responsibilities |

|---|---|

| Project Manager | Overseeing the entire project lifecycle, from planning to completion, managing timelines, budgets, and communication |

| Estimator | Developing accurate cost estimates for materials, labor, and project contingencies; ensuring the budget aligns with project requirements |

| Site Supervisor | Ensuring the safety and compliance of the worksite, coordinating daily tasks and activities, and monitoring progress. |

| Metal Fabricator | Producing metal cladding components, ensuring quality control, and adherence to design specifications. |

| Installer | Installing metal cladding elements according to specifications; ensuring proper fastening and finish quality.y |

Project Management and Execution: Metal Cladding Contractors

Effective project management is crucial for the successful execution of any metal cladding project. This involves meticulous planning, consistent communication, and vigilant quality control measures throughout the project lifecycle. Careful attention to potential risks and proactive mitigation strategies is vital to staying on schedule and within budget.

Proper project management ensures the project meets the client’s expectations, adheres to safety standards, and delivers a high-quality final product. This includes a well-defined process, clear communication channels, and dedicated personnel to handle the complexities of metal cladding.

Project Planning and Design

The initial design phase is critical, influencing all subsequent stages. This includes meticulous site surveys, detailed drawings, and precise material specifications. The contractor must collaborate closely with the client to fully understand project requirements and any unique site conditions. Architectural plans must be interpreted accurately to determine material needs and installation specifications. A robust design review process helps to identify and address potential issues early, reducing costly revisions later.

Project Execution and Timeline Management

The execution phase requires strict adherence to the project schedule. Key activities include material procurement, site preparation, fabrication, and installation. Effective scheduling, coupled with accurate material ordering and delivery timelines, is paramount to avoiding delays. Contingency planning is essential to address unexpected issues, such as inclement weather or material shortages. Realistic scheduling and contingency measures minimize the impact of unexpected events.

Quality Control Measures

Maintaining quality control is a continuous process throughout the project lifecycle. This involves implementing rigorous inspection procedures at various stages. Inspection standards should be clearly defined and documented. Independent inspections, conducted by qualified personnel, can help ensure adherence to specifications and standards. Regular progress meetings and reporting to the client are vital to transparent communication. This approach fosters trust and provides an opportunity for early problem resolution.

Common Challenges and Solutions

Metal cladding projects can encounter various challenges, including site access limitations, complex architectural details, and unforeseen material issues. Careful site analysis and thorough pre-planning can minimize site access problems. Detailed design reviews and mock-ups help to address complex architectural challenges. Developing strong relationships with reliable suppliers and establishing clear communication channels with them can minimize material issues.

Communication and Collaboration

Effective communication and collaboration among the contractor, client, and other stakeholders are crucial for project success. Regular progress meetings, clear documentation, and prompt responses to inquiries foster a collaborative environment. Transparent communication helps to address issues promptly and maintain a positive working relationship. Establishing a dedicated point of contact for all parties facilitates communication and minimizes misunderstandings.

Typical Project Phases and Deliverables

| Project Phase | Deliverables |

|---|---|

| Design and Planning | Detailed Drawings, Material Specifications, Site Survey Report, Budget Estimate |

| Procurement | Ordered Materials, Material Inspection Reports, Supplier Contracts |

| Site Preparation | Site Conditions Report, Temporary Structures, Safety Plans |

| Fabrication | Fabricated Components, Quality Control Reports |

| Installation | Installed Cladding System, Inspection Reports |

| Final Inspection and Acceptance | Final Inspection Report, Project Closure Documents |

Closing Notes

In conclusion, navigating the complexities of metal cladding projects requires careful consideration of material selection, contractor evaluation, and project management. This guide provides a structured approach, equipping readers with the knowledge needed to make informed decisions throughout the process. From selecting the best materials to managing timelines and budgets, a well-informed approach is essential for success. By understanding the nuances of each step, from initial design to final inspection, you can ensure a positive outcome for your metal cladding project.