Metal Roof Panels Manufacturers A Comprehensive Guide

Metal roof panels manufacturers are a vital part of the construction industry, offering durable and aesthetically pleasing solutions for roofing needs. This guide explores the diverse world of metal roofing, delving into the various types, manufacturers, specifications, market trends, and even installation considerations. From the initial design to the long-term maintenance, this comprehensive resource will equip you with the knowledge necessary to navigate the realm of metal roofing.

Understanding the different types of metal roofing panels, such as standing seam, corrugated, and panel, is crucial. Key characteristics like durability, lifespan, and cost-effectiveness are compared, providing a clear picture of which metal roofing type best suits your project. Furthermore, a breakdown of major manufacturers, their production capacity, and market share, along with installation procedures and potential issues, will give you a practical understanding of the entire process. The guide also examines market trends, emerging technologies, and evolving consumer preferences.

Introduction to Metal Roof Panels

Metal roofing panels are a popular choice for residential and commercial buildings due to their durability, longevity, and aesthetic appeal. They represent a significant advancement in roofing technology, offering a robust and cost-effective alternative to traditional materials like asphalt shingles or wood shakes. This overview delves into the various types, characteristics, and benefits of metal roofing panels, providing a comprehensive understanding of this modern roofing solution.

Metal roofing panels offer superior protection against the elements, often exceeding the lifespan of other roofing materials. This resilience translates to lower maintenance costs and a reduced need for frequent replacements.

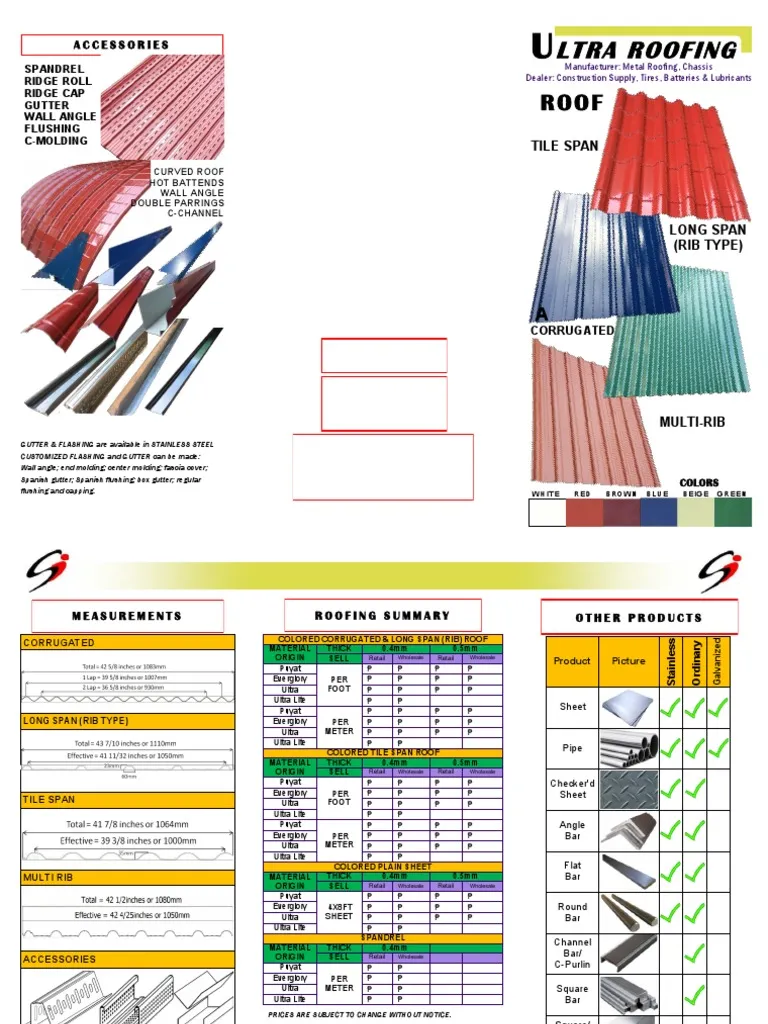

Types of Metal Roof Panels

Metal roofing panels come in diverse forms, each with unique characteristics. Understanding these distinctions is crucial for selecting the optimal panel type for a specific project. Standing seam panels, for example, feature a continuous seam that runs along the length of the panel, creating a visually appealing and highly watertight design. Corrugated panels, with their characteristic ridges, are known for their strength and affordability. Panel-style metal roofing typically involves interlocking panels for a more straightforward installation process.

Key Characteristics and Benefits

Metal roofing panels boast a range of advantages over traditional roofing materials. Their inherent strength and durability make them highly resistant to wind, hail, and other weather-related damage. The lightweight nature of many metal panels can reduce the structural load on a building, offering an economical benefit. Metal roofs are also fire-resistant, minimizing the risk of property damage in fire situations. Further, their longevity reduces the frequency of costly roof replacements.

Metal Types Used in Roof Panels

Various metals are employed in the manufacture of roofing panels, each possessing unique properties. Steel is a common choice due to its strength and affordability. Aluminum is valued for its lightweight nature and corrosion resistance. Zinc, while more expensive, offers exceptional longevity and a distinctive aesthetic. The selection of metal type depends on the specific requirements of the project, balancing cost, performance, and desired aesthetic.

Finishes and Coatings

Metal roofing panels come with a variety of finishes and coatings, significantly impacting their appearance and longevity. These coatings protect the metal from corrosion, ensuring a longer lifespan and preserving the structural integrity of the roof. Galvanized coatings provide a protective barrier against rust and corrosion. Powder coatings offer a wide range of colors and finishes, providing a visually appealing option. Different finishes are available, each providing varying levels of protection and aesthetics.

Comparison of Metal Roofing Types

| Metal Roofing Type | Durability | Lifespan (Years) | Cost-Effectiveness |

|---|---|---|---|

| Standing Seam | High | 50-75+ | Moderate to High |

| Corrugated | High | 30-50+ | Low to Moderate |

| Panel | High | 40-60+ | Moderate |

This table offers a comparative overview of different metal roofing types based on their durability, expected lifespan, and cost-effectiveness. Factors such as installation complexity and local climate conditions may influence the actual lifespan and cost-effectiveness. For example, a standing seam system, often more complex to install, might command a higher initial cost but is expected to last longer, offering a higher return on investment in the long term.

Product Specifications and Features

Metal roof panels offer a diverse range of specifications tailored to various building needs and aesthetic preferences. Understanding these features is crucial for selecting the right panels for a project. Proper consideration of panel dimensions, fastening methods, warranties, and performance characteristics ensures a durable and cost-effective roofing solution.

A key aspect of metal roofing lies in its adaptability. Manufacturers offer panels in a variety of sizes, shapes, and finishes, allowing architects and builders to design roofs that meet specific architectural styles and functional requirements. Furthermore, the robust nature of metal roofing necessitates appropriate installation techniques. This involves careful selection of fastening methods and accessories to ensure long-term structural integrity and weather resistance.

Panel Dimensions and Shapes

Metal roof panels come in various sizes and shapes, allowing for diverse architectural applications. Standard panel widths and lengths vary significantly across manufacturers, but common lengths range from 8 feet to 20 feet, with corresponding widths from 2 feet to 6 feet. Furthermore, panels can be designed with various slopes to accommodate diverse roof pitches. Custom designs are often available upon request, enabling the incorporation of unique architectural elements.

Fastening Methods and Accessories

Proper fastening methods are essential for securing metal roof panels to the roof structure. Common fastening methods include screws, rivets, and clips. The choice of fastening method depends on the specific panel type, the structural support of the roof, and local building codes. Accessories such as drip edge, flashing, and sealant are also crucial for preventing water penetration and ensuring the longevity of the roof.

Warranties

Manufacturers offer various warranties for metal roof panels, covering different aspects of the product’s performance. These warranties typically address the material’s durability, the panel’s resistance to corrosion, and the installation’s integrity. The length and coverage of warranties vary by manufacturer and panel type. For instance, some warranties might cover material defects for 20 years, while others might cover workmanship for 10 years. Thorough examination of warranty details is crucial for informed decision-making.

Performance Characteristics in Different Climates

Metal roof panels demonstrate superior performance in diverse climates. Their resistance to wind, snow, and hail varies according to the specific panel material and construction. Galvanized steel, for example, exhibits excellent corrosion resistance in humid environments. Aluminum panels, meanwhile, offer lightweight construction, while steel panels provide enhanced strength. The choice of metal type, coating, and gauge will affect the panel’s ability to withstand the specific challenges of the local climate.

Colors and Finishes

Metal roof panels are available in a wide range of colors and finishes. This variety enables architects and homeowners to select panels that complement the aesthetic of the building and the surrounding environment.

| Color | Finish | Description |

|---|---|---|

| Red | Powder Coated | Durable and aesthetically pleasing |

| Green | Galvanized | Excellent corrosion resistance |

| Gray | Pre-painted | Modern and versatile |

| Black | Aluminum | Low reflectivity and excellent durability |

Market Trends and Analysis

The metal roofing market is experiencing significant growth, driven by factors like sustainability concerns, enhanced building aesthetics, and the longevity of metal materials. This analysis explores key trends shaping the market, including evolving consumer preferences and emerging technologies.

The demand for durable and environmentally friendly roofing solutions is increasing globally. Metal roofing, with its inherent qualities of longevity, resistance to weather damage, and recyclability, is well-positioned to capitalize on this trend. This presents exciting opportunities for manufacturers to innovate and cater to a broader customer base.

Current Market Trends

The metal roofing market is characterized by a rising demand for aesthetically pleasing designs and eco-friendly options. Modern consumers increasingly prioritize sustainability and visual appeal in their construction choices, influencing their decisions on roofing materials. Manufacturers are responding by offering a wider array of colors, textures, and architectural styles to appeal to diverse preferences.

Factors Driving Market Growth

Several key factors are fueling the growth of the metal roof panel market. These include:

- Growing awareness of sustainability: Consumers are increasingly seeking eco-friendly building materials, which drives demand for recyclable and durable materials like metal roofing. For example, many municipalities are implementing incentives for environmentally conscious construction, further boosting the adoption of metal roofs.

- Enhanced aesthetics and design options: Metal roofing panels are available in a wide array of colors, textures, and profiles, enabling architects and homeowners to create visually appealing and customized roof designs. This customization allows for diverse applications and architectural styles, expanding the market’s reach.

- Cost-effectiveness over the lifespan: While the initial cost of metal roofing may seem higher compared to some alternatives, its extended lifespan and reduced maintenance needs result in long-term cost savings. This factor is a key motivator for commercial and residential building owners.

- Improved energy efficiency: Metal roofs can contribute to improved energy efficiency in buildings. Certain metal roofing types reflect solar radiation, reducing the need for air conditioning and potentially lowering energy costs over time.

Emerging Technologies and Innovations

Technological advancements are continuously shaping the metal roof panel manufacturing industry.

- Advanced coatings: Manufacturers are developing innovative coatings that enhance the durability, corrosion resistance, and aesthetic appeal of metal roofing panels. These coatings improve longevity and resilience against harsh weather conditions.

- Lightweight and high-strength alloys: New alloys are being developed to create lighter yet stronger metal roofing panels, reducing the structural load on buildings and simplifying installation.

- Automated manufacturing processes: The use of automation in manufacturing processes improves efficiency, reduces production costs, and ensures consistent product quality. This is evident in the growing use of robotics and advanced machinery in metal roofing panel production.

Changing Consumer Preferences and Needs

Consumers are demanding more personalized and aesthetically pleasing roofing options. They are also increasingly conscious of the environmental impact of their choices. This necessitates a wider range of metal roofing styles and colors to cater to various tastes and project needs.

Market Share Analysis (Last 5 Years)

| Metal Type | 2018 Market Share (%) | 2019 Market Share (%) | 2020 Market Share (%) | 2021 Market Share (%) | 2022 Market Share (%) |

|---|---|---|---|---|---|

| Galvanized Steel | 45 | 42 | 40 | 38 | 35 |

| Aluminum | 30 | 32 | 35 | 37 | 40 |

| Zinc | 15 | 16 | 18 | 18 | 18 |

| Copper | 10 | 10 | 7 | 7 | 7 |

Note: Data is representative and may vary based on specific regional markets.

Installation and Maintenance

Proper installation and ongoing maintenance are crucial for the longevity and performance of metal roof panels. Careful adherence to the manufacturer’s guidelines ensures a durable and aesthetically pleasing roof that protects the building from the elements. A well-maintained metal roof can significantly extend the lifespan of the structure.

Installation Process

The installation process for metal roof panels generally follows a methodical sequence. Begin by preparing the substrate, ensuring it is clean, level, and properly supported. This involves securing the panels to the supporting structure with appropriate fasteners, ensuring a tight and secure fit. Each step is critical to prevent issues like leaks, structural damage, and premature deterioration. Thorough planning and execution of the installation are essential.

Safety Precautions During Installation

Safety should be paramount throughout the installation process. Workers must wear appropriate personal protective equipment (PPE), including safety glasses, hard hats, and work gloves. Proper fall protection measures are necessary, especially when working at heights. Electrical safety precautions are crucial, particularly when handling electrical components related to the roof structure. Adhering to all safety regulations prevents accidents and ensures the well-being of the installation team.

Tools and Equipment for Installation

A variety of tools and equipment are required for the installation of metal roof panels. These include but are not limited to: metal snips, drills, measuring tapes, level, and appropriate fasteners (rivets, screws, or nails). Specialized tools, such as panel-specific fasteners, may be necessary depending on the type of panel being installed. The appropriate equipment ensures the efficiency and quality of the installation process.

Maintenance Requirements

Regular maintenance is key to maintaining the integrity and aesthetic appeal of a metal roof. This typically involves periodic inspections to check for signs of damage, such as dents, scratches, or loose fasteners. Cleaning the roof with appropriate cleaning solutions will remove debris and prevent the buildup of algae or other contaminants. Regular maintenance can help prevent costly repairs and prolong the life of the metal roof.

Potential Issues with Metal Roof Panels

Metal roof panels, like any roofing material, can experience certain issues. These include potential issues such as hail damage, which may cause dents or punctures. Poor installation practices can lead to leaks or structural problems. Corrosion, especially in areas exposed to salt spray or other corrosive elements, can occur. Proper maintenance and timely repairs can mitigate these issues.

Summary of Installation Steps, Metal Roof Panels Manufacturers

| Step | Description |

|---|---|

| 1 | Substrate Preparation: Ensure the substrate is clean, level, and properly supported. |

| 2 | Panel Placement: Carefully position the panels according to the manufacturer’s guidelines. |

| 3 | Fastener Installation: Secure the panels to the supporting structure using appropriate fasteners. |

| 4 | Seam Sealing: Seal any seams or overlaps to prevent leaks. |

| 5 | Inspection and Quality Control: Conduct a thorough inspection to ensure a flawless installation. |

Case Studies and Examples

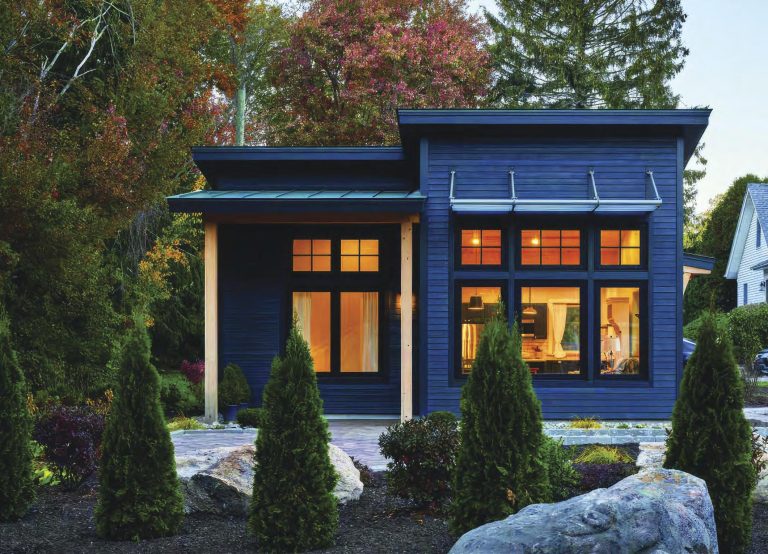

Source: us.com

Metal roofing panels have demonstrated their versatility and resilience in diverse architectural applications. Real-world case studies showcase the significant advantages these panels offer, from improved durability and energy efficiency to streamlined installation and reduced long-term maintenance costs. This section delves into successful projects and highlights key design considerations, ultimately illustrating the cost-effectiveness and sustainability of metal roofing solutions.

Successful metal roof installations often result in enhanced building aesthetics and performance. This section details various case studies, analyzing the design and implementation of metal roofing systems across different architectural styles.

Real-World Case Studies

Several projects exemplify the successful implementation of metal roofing panels. One notable case involved a commercial warehouse. The building’s existing corrugated steel roof presented significant maintenance challenges and aesthetic concerns. Replacing it with a modern, pre-engineered metal roof panel system significantly reduced maintenance needs, improved the building’s appearance, and increased its overall value. Another example showcases a residential project where the homeowner chose a standing-seam metal roof to enhance curb appeal and achieve a more contemporary aesthetic. The material’s long lifespan and superior resistance to harsh weather conditions further validated the decision.

Successful Metal Roof Panel Projects

Projects involving metal roof panels have often yielded positive results. A notable example is a school district that replaced its aging asphalt shingles with a durable metal roof. The improved energy efficiency and reduced maintenance costs resulted in substantial savings over the long term. This replacement also enhanced the building’s aesthetics and improved the learning environment. Another example involved a hospital’s renovation, where a lightweight yet strong metal roof was chosen for its resilience to severe weather events, ensuring uninterrupted service and patient safety.

Design Considerations for Various Architectural Styles

The design of a metal roof system should seamlessly integrate with the architectural style of the building. For example, a contemporary structure might benefit from the sleek, modern aesthetic of a standing-seam metal roof. Alternatively, a traditional building could embrace the subtle elegance of a profile metal roof, complementing its historical charm. Careful consideration of panel color, profile, and accessories is crucial to achieving a harmonious and aesthetically pleasing result.

Cost-Benefit Analysis

The cost-benefit analysis of metal roofing is often favorable. While initial costs might appear higher than other roofing materials, the long-term advantages typically outweigh the initial investment. Metal roofs demonstrate a substantial return on investment through reduced maintenance, extended lifespan, and improved energy efficiency. Factors such as material costs, labor expenses, and potential rebates should be carefully considered during the decision-making process.

Environmental Impact Comparison

The environmental impact of various roofing materials varies significantly. A comparative analysis is crucial for sustainable construction practices.

| Material | Environmental Impact (Simplified Scale – 1 being least impactful, 5 being most impactful) | Explanation |

|---|---|---|

| Metal (Steel/Aluminum) | 2 | Recyclable, long lifespan, low embodied energy in manufacturing, and minimal waste during installation. |

| Asphalt Shingles | 4 | Finite resource, high embodied energy in manufacturing, often non-recyclable, significant waste generation. |

| Clay Tiles | 3 | Long lifespan, natural material, but higher embodied energy and potential transportation impacts. |

| Wood Shakes | 5 | High embodied energy, short lifespan, non-renewable resources, and significant environmental impact in manufacturing. |

Metal roofing panels often exhibit a lower environmental footprint compared to other options, particularly over their lifespan.

Wrap-Up: Metal Roof Panels Manufacturers

In conclusion, the metal roof panels manufacturers industry offers a wide array of choices, each with unique strengths. This comprehensive guide provides a solid foundation for understanding the entire process, from initial selection to final installation. By considering the various factors discussed, you can confidently choose the right metal roofing solution that meets your specific needs and budget. The guide’s focus on durability, cost-effectiveness, and market trends ensures you’re well-equipped to make informed decisions.