Railroad Retaining Wall Design & Construction

Railroad retaining wall structures are crucial for safe and efficient rail operations. They play a vital role in supporting the ground alongside railway tracks, preventing landslides, and ensuring the stability of the railway infrastructure. This exploration delves into the intricacies of designing, constructing, and maintaining these essential components of railway systems.

This comprehensive guide covers various aspects, from the initial definition and types of retaining walls to detailed design considerations, construction methods, maintenance procedures, and even environmental and safety protocols. Understanding these factors is critical for ensuring the long-term reliability and safety of railway lines.

Introduction to Railroad Retaining Walls

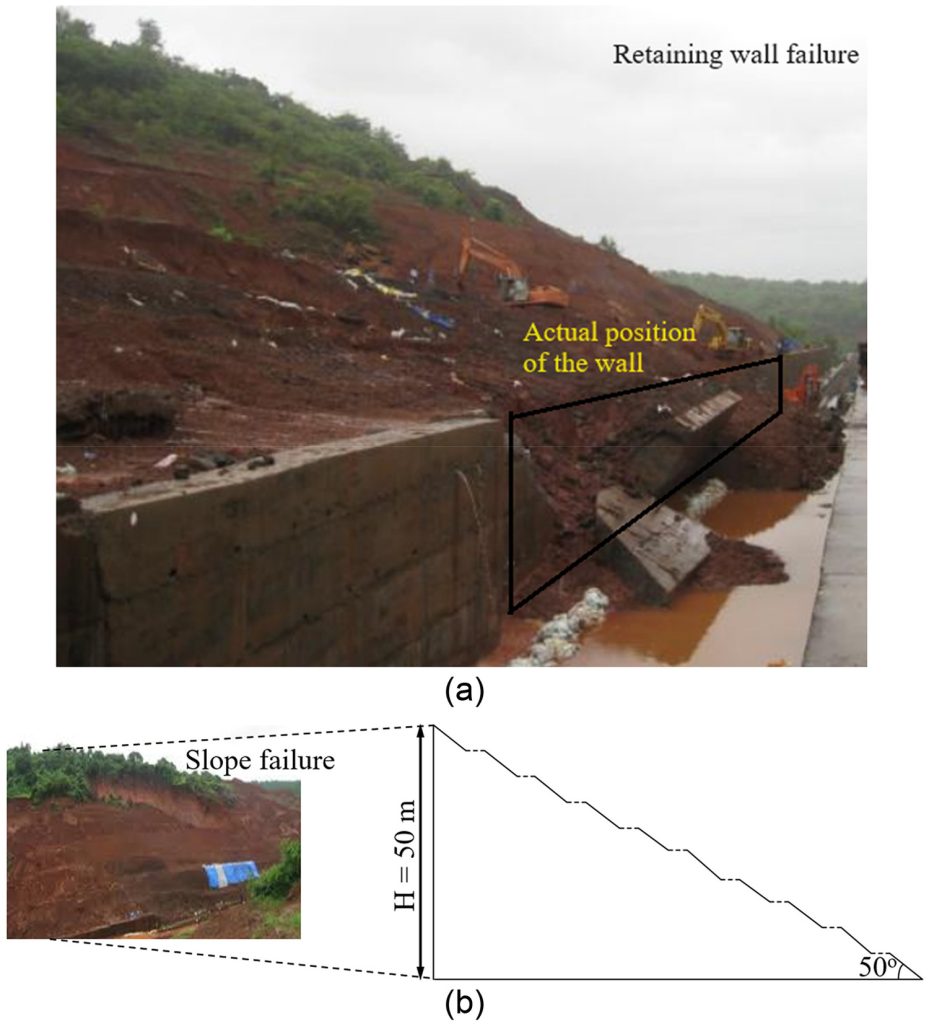

Railroad retaining walls are crucial infrastructure components designed to stabilize the ground along railway lines. They play a vital role in preventing landslides, erosion, and other geotechnical issues that could compromise the safety and operation of railway systems. These walls act as a barrier, supporting the earth and preventing it from encroaching on the railway tracks.

These structures are engineered to withstand significant loads, particularly from the weight of the earth and the dynamic forces associated with train traffic. Careful consideration of soil conditions, groundwater levels, and anticipated seismic activity is essential during the design and construction phases.

Definition of Railroad Retaining Walls

Railroad retaining walls are engineered structures specifically designed to retain soil and earth masses along railway corridors. Their primary function is to prevent soil from sliding or collapsing onto the railway tracks, ensuring the safety of train operations and the stability of the surrounding infrastructure.

Primary Functions of Railroad Retaining Walls

The primary functions of railroad retaining walls are multifaceted, encompassing both safety and operational considerations. They prevent landslides and erosion, safeguarding railway lines from natural hazards. Further, they support the stability of the surrounding environment, minimizing the risk of damage to nearby property and infrastructure.

Types of Railroad Retaining Walls

Various types of retaining walls are employed in railway projects, each tailored to specific site conditions and design considerations. Common types include gravity, anchored, and reinforced concrete walls.

Common Materials Used in Railroad Retaining Walls

A variety of materials are used in the construction of railroad retaining walls, each with its own set of properties and characteristics. Concrete, steel, and various types of soil reinforcement are frequently used depending on the specific project requirements and budget constraints. Proper material selection is critical to the wall’s long-term performance and structural integrity.

Comparison of Different Wall Types

| Wall Type | Pros | Cons |

|---|---|---|

| Gravity | Relatively simple to construct, cost-effective in some cases, and good stability for stable soil conditions. | Can be bulky and require substantial space, less effective in areas with high seismic activity or unstable soil conditions, limited height capacity. |

| Anchored | Higher load-bearing capacity than gravity walls, suitable for challenging soil conditions, and potentially higher height capacity. | More complex construction, requiring more specialized materials and installation, potential for anchor failure if not properly designed or maintained. |

| Reinforced Concrete | High load-bearing capacity, high durability, long lifespan, suitable for a wide range of soil conditions, and can be designed for high seismic activity. | Relatively high construction costs, more complex design and construction process, and potentially higher material costs. |

Design Considerations

Proper design of railroad retaining walls is crucial for ensuring the safety and functionality of the railway infrastructure. These walls must withstand significant loads, both static and dynamic, imposed by the tracks, trains, and the surrounding soil conditions. A comprehensive design approach incorporating geotechnical analysis, material properties, seismic considerations, and careful load estimations is paramount.

Careful consideration of all contributing factors, including soil conditions, seismic activity, and train loads, is essential for a robust and reliable design. This ensures the retaining wall can effectively support the railway infrastructure while maintaining stability over its operational lifespan.

Geotechnical Investigations

Thorough geotechnical investigations are fundamental to understanding the soil conditions at the site. These investigations provide critical data on soil properties, such as bearing capacity, shear strength, and settlement potential. This data is essential for determining the stability of the retaining wall and selecting appropriate design parameters. Results from laboratory testing, including soil classification, strength tests, and permeability tests, offer valuable insights. In-situ testing methods, such as cone penetration testing (CPT) and vane shear tests, provide further information on the soil’s behavior under load.

Soil Properties

Soil properties significantly influence the design of railroad retaining walls. The shear strength of the soil, its bearing capacity, and the potential for settlement or deformation are critical factors. The soil’s permeability dictates the potential for water infiltration and the possibility of groundwater pressure buildup. Different soil types exhibit distinct behaviors under load, requiring tailored design approaches. For instance, cohesive soils respond differently to loads compared to granular soils. Understanding the soil’s characteristics, including its plasticity index and grain size distribution, is vital for determining its load-bearing capacity.

Seismic Considerations

Seismic activity can exert substantial forces on retaining walls, potentially leading to instability or damage. Designers must incorporate seismic considerations to ensure the wall’s ability to withstand earthquake-induced ground motions. The design should account for the potential for lateral earth pressures induced by seismic events. Analysis methods, such as pseudo-static analysis and dynamic analysis, are employed to assess the wall’s response to seismic loading. The selection of an appropriate seismic design category, based on local seismic hazard maps, is critical. Real-world examples of seismic events impacting retaining walls provide valuable lessons for designing robust and resilient structures.

Accounting for Railroad Loads

The weight and pressure exerted by railroad tracks and trains are substantial and must be accurately accounted for in the design process. Detailed calculations of the static and dynamic loads from passing trains are crucial. The weight distribution of the train, including the number of axles and their load capacity, is factored into the design. Consideration of the train’s speed and the potential for impact forces is also important. The design should incorporate appropriate safety factors to mitigate the risk of damage or failure. Historical data on train loads and typical train configurations are often used to establish realistic design loads.

Design Checklist for Railroad Retaining Walls

A well-defined checklist helps ensure that all critical aspects of the design process are addressed. This checklist should cover various stages, from initial site investigations to final construction.

- Geotechnical Investigation Report Review: Thorough assessment of the soil characteristics and site conditions is essential.

- Seismic Analysis: Assessment of potential seismic forces and appropriate design considerations for earthquake resistance.

- Load Calculation: Precise calculation of the static and dynamic loads from the railroad tracks and trains.

- Material Selection: Choice of appropriate materials for the retaining wall structure and foundation, considering durability and strength requirements.

- Drainage System Design: Implementation of an effective drainage system to prevent water buildup and mitigate potential issues.

- Construction Quality Control: Strict adherence to construction specifications and quality assurance measures during construction.

Construction Methods

Constructing railroad retaining walls involves a variety of methods tailored to specific wall types and site conditions. Proper selection and execution are crucial for ensuring the stability, longevity, and safety of the structure. Careful consideration of soil properties, anticipated loads, and local regulations is paramount.

Gravity Retaining Wall Construction

Gravity retaining walls rely on their weight to resist the pressure of the retained soil. Construction of these walls typically begins with site preparation. This involves clearing the area, excavating the foundation trench to the specified depth, and compacting the soil. Precise leveling is essential to ensure a stable base. Formwork is erected to define the wall’s shape. Reinforcing steel, if required, is placed within the formwork, followed by concrete pouring and curing. The concrete must be placed and compacted in layers to minimize voids and ensure proper strength. Curing procedures, such as covering the concrete with plastic sheeting or using moisture-retaining agents, are essential for optimal strength development. Finally, the formwork is removed once the concrete has reached sufficient strength, and the wall is inspected for any defects.

Anchored Retaining Wall Installation

Anchored retaining walls utilize external anchors to resist the earth pressure. The installation process begins with excavating the foundation trench and preparing the anchor bed. The anchors, typically steel bars or cables, are then precisely placed and secured to the wall. The wall itself is constructed, typically using reinforced concrete, in sections to accommodate the anchor placement. Special care must be taken during anchor installation to ensure precise alignment and proper tensioning. The anchoring system is meticulously checked for integrity, ensuring that the anchors are firmly embedded in the ground and that the wall can withstand the anticipated loads.

Reinforced Concrete Retaining Wall Construction

Reinforced concrete retaining walls combine the strength of concrete with steel reinforcement for enhanced stability. A typical construction sequence involves site preparation, excavation, and foundation preparation. Steel reinforcement is placed within the formwork, and concrete is poured and cured following a precise schedule. The formwork is carefully removed once the concrete has reached the required strength. A key aspect of the process is the reinforcement pattern, which is carefully designed to counteract the lateral earth pressures. The reinforcement placement and concrete quality are critically important to the overall stability and longevity of the structure.

Construction Challenges and Solutions

Construction of retaining walls can present various challenges, such as difficult terrain, challenging soil conditions, or tight project deadlines. For example, unstable ground conditions might require special ground improvement techniques, such as soil stabilization or deep foundations. Accurately predicting and accounting for the soil properties is critical to the project’s success. Delays in material delivery or unforeseen issues can also pose challenges. Careful project planning, contingency plans, and effective communication among all stakeholders can mitigate such risks. Proper site assessment, detailed design, and diligent quality control procedures are critical to minimize potential issues and ensure the project is completed safely and efficiently.

Flowchart: Reinforced Concrete Retaining Wall Construction

| Step | Description |

|---|---|

| 1 | Site Preparation and Excavation |

| 2 | Foundation Preparation (compaction, leveling) |

| 3 | Formwork Erection |

| 4 | Reinforcement Placement |

| 5 | Concrete Pouring and Compaction |

| 6 | Concrete Curing |

| 7 | Formwork Removal |

| 8 | Inspection and Quality Control |

| 9 | Backfilling and Finishing |

Maintenance and Repair

Proper maintenance and repair are crucial for the longevity and safety of railroad retaining walls. Neglecting these aspects can lead to costly repairs, potential damage to the railroad infrastructure, and even safety hazards for personnel and the public. A proactive approach to maintenance, including regular inspections and timely repairs, minimizes these risks and maximizes the operational lifespan of the retaining walls.

Regular inspections are vital for identifying potential issues early on, allowing for prompt repairs before they escalate into major problems. This proactive approach is more cost-effective and safer than waiting for a catastrophic failure. Addressing issues early minimizes disruption to train operations and reduces the likelihood of significant damage.

Importance of Routine Inspections

Regular inspections are essential to detect early signs of deterioration and structural weakness in railroad retaining walls. This proactive approach is key to preventing costly repairs and ensuring the safety of the infrastructure and surrounding areas. The frequency of inspections should be determined based on the specific environmental conditions, the material used in construction, and the history of the retaining wall.

Common Signs of Deterioration

Several indicators suggest deterioration in railroad retaining walls. These include cracks in the wall structure, settlement or displacement of the wall, signs of water intrusion or leakage, and any changes in the slope stability of the retaining wall. Careful observation and documentation of these signs can facilitate early identification and effective preventative measures.

- Cracks: Cracks, both large and small, can indicate stress or structural weakness. Their presence warrants immediate attention and further investigation to determine the cause and extent of the damage.

- Settlement/Displacement: Any observable settlement or displacement of the retaining wall suggests potential instability. This requires immediate evaluation and possible corrective action.

- Water Intrusion/Leakage: Water intrusion can cause erosion and weakening of the foundation and supporting structures. Visible water leakage, seepage, or pooling around the wall is a strong indicator of potential issues that require attention.

- Slope Instability: Changes in the slope stability, including the presence of cracks, slumps, or other signs of instability, should be promptly addressed.

Procedures for Repairing Damaged Retaining Walls

Repair procedures for damaged retaining walls should be tailored to the specific type of damage and the structural integrity of the wall. Proper documentation and a thorough assessment of the damage are crucial for planning effective repairs.

- Assessment: A comprehensive assessment of the damaged area is necessary to identify the extent of the damage, including the cause of the damage, and to develop a suitable repair plan.

- Preparation: The affected area needs careful preparation, including clearing debris and any unstable material. Proper support structures may be required to prevent further damage during the repair process.

- Repair Execution: The repair process should involve the use of appropriate materials and techniques. This may include grouting, patching, or reinforcement to stabilize the affected area.

- Post-Repair Inspection: A post-repair inspection is essential to ensure the effectiveness of the repair. This step verifies the structural integrity of the repaired area and confirms that the wall is now stable.

Preventive Maintenance Strategies

Implementing preventive maintenance strategies can significantly extend the lifespan of railroad retaining walls. Regular inspections, proper drainage, and timely addressing of minor issues can prevent major damage. A proactive approach minimizes costly repairs and maintains the safety of the infrastructure.

- Drainage Systems: Implementing and maintaining effective drainage systems around the retaining wall prevents water accumulation and subsequent erosion. Proper grading and drainage channels are essential to redirect water away from the wall.

- Erosion Control: Employing erosion control measures, such as planting vegetation or using geotextiles, helps prevent soil erosion and protects the base of the retaining wall.

- Regular Inspections: Regular, scheduled inspections are crucial for early detection of developing issues, allowing for timely interventions and preventing minor problems from escalating.

Checklist for Periodic Inspections

A well-defined checklist is critical for ensuring thoroughness and consistency during periodic inspections. This checklist should cover all potential areas of concern and include visual observations, measurements, and any necessary documentation.

| Inspection Item | Criteria | Action Required |

|---|---|---|

| Wall Structure | Cracks, bulges, settlements, or signs of displacement. | Document findings, assess severity, and schedule repairs as needed. |

| Drainage System | Blockages, clogs, or signs of water pooling. | Clear blockages, repair damage, and adjust drainage systems as necessary. |

| Surrounding Ground | Erosion, slope instability, or signs of settlement. | Implement erosion control measures, regrade slopes, and stabilize the surrounding ground. |

| Foundation | Signs of damage, settlement, or instability. | Evaluate foundation condition and implement necessary repairs. |

Case Studies: Railroad Retaining Wall

Source: rochaconstruction.com

Railroad retaining wall projects present a diverse range of challenges, and successful implementation hinges on meticulous design, appropriate construction methods, and robust long-term maintenance strategies. Analyzing past projects provides valuable insights into effective solutions and potential pitfalls, enabling informed decision-making for future projects.

Successful Railroad Retaining Wall Projects

Several successful railroad retaining wall projects showcase innovative designs and effective construction techniques. These projects demonstrate how careful planning and execution can mitigate potential risks and ensure the longevity of the infrastructure. Project A, a significant undertaking involving a high-volume rail line, utilized a reinforced concrete cantilever wall design. This approach effectively addressed the project’s unique challenges, including seismic activity and heavy rail traffic. The project adhered to stringent safety regulations throughout the construction process, minimizing disruption to rail operations.

Challenges Encountered and Solutions Implemented

Construction projects often face unforeseen obstacles. Project B, a project in a challenging terrain environment, encountered difficulties with soil instability. The project team effectively addressed this by implementing extensive soil stabilization measures. These measures involved the installation of geogrid reinforcement and deep soil mixing, thereby enhancing the stability of the retaining wall foundation. The successful completion of this project highlighted the importance of adapting design strategies to site-specific conditions. Project C, characterized by limited space and tight construction deadlines, adopted a prefabricated modular wall system. This approach minimized on-site construction activities, facilitating rapid project completion without compromising safety or quality.

Impact on Project Timelines and Budgets

The design of railroad retaining walls plays a critical role in determining project timelines and budgets. A well-designed retaining wall can reduce the need for extensive site preparation and construction activities, thus shortening the project timeline and lowering overall costs. Projects with robust design considerations, including geotechnical analysis and detailed construction plans, often experience smoother execution, leading to more predictable project timelines and budgets. Conversely, inadequate design or unforeseen ground conditions can significantly impact timelines and budgets.

Long-Term Performance of Various Wall Types

The long-term performance of railroad retaining walls depends on various factors, including material selection, design specifications, and environmental conditions. Gravity walls, typically composed of concrete or stone, offer a cost-effective solution for stable soil conditions. However, they might require extensive foundation preparation. Reinforced concrete cantilever walls provide enhanced stability and load-bearing capacity, particularly in areas prone to seismic activity or high traffic. Their higher initial cost is often offset by long-term performance advantages. Prefabricated modular walls offer the advantage of faster construction times, but their suitability depends on site access and logistical considerations. Monitoring and regular maintenance are essential for all types of retaining walls to ensure their long-term stability and safety.

Summary of Key Lessons Learned

| Project Name | Wall Type | Challenges | Solutions |

|---|---|---|---|

| Project A | Reinforced Concrete Cantilever | Seismic activity, heavy rail traffic | Stringent safety regulations, meticulous design |

| Project B | Composite Reinforced Wall | Soil instability | Geogrid reinforcement, deep soil mixing |

| Project C | Prefabricated Modular | Limited space, tight deadlines | Minimized on-site construction, prefabrication |

Environmental Impact

Source: pinimg.com

Railroad retaining walls, while crucial for safety and infrastructure stability, can have environmental consequences. Careful planning and construction practices are essential to minimize these impacts and ensure sustainability. Understanding the potential environmental effects and implementing mitigation strategies is paramount for responsible infrastructure development.

Proper assessment of the site’s ecological characteristics and the potential for disruption to existing ecosystems is critical. This includes identifying sensitive habitats, endangered species, and water resources that might be affected by the project. A thorough environmental impact assessment (EIA) is a critical first step in this process.

Potential Environmental Impacts

The construction of railroad retaining walls can lead to habitat loss or fragmentation, potentially affecting local biodiversity. Disruption of water bodies, such as streams and wetlands, can alter hydrological cycles. Dust and noise pollution during construction can impact air and sound quality. The use of certain materials in construction can introduce contaminants into the soil or water. Furthermore, improper waste disposal practices can lead to soil and water contamination.

Mitigation Measures

Various measures can be implemented to mitigate the environmental impacts of railroad retaining wall construction. These include:

- Careful site selection and design to minimize disruption of sensitive habitats. Prioritizing areas with minimal ecological value or impact helps protect sensitive environments. Careful consideration of the wall’s footprint is critical.

- Employing environmentally friendly construction methods, such as minimizing excavation and using sustainable materials. This can include utilizing prefabricated wall segments to reduce on-site disturbance.

- Implementing noise and dust control measures during construction. Using sound barriers and dust suppression techniques helps mitigate the impact on nearby communities and ecosystems.

- Implementing erosion control measures to prevent soil loss and protect water quality. This includes the use of vegetation barriers and sediment control measures.

- Proper waste management and disposal protocols to prevent contamination. Strict adherence to waste management regulations and practices is vital for protecting the environment.

Sustainable Design Practices

Adopting sustainable design practices is crucial for reducing the environmental footprint of railroad retaining walls. This involves using environmentally friendly materials, minimizing construction waste, and considering the long-term maintenance needs of the structure.

- Prioritizing the use of recycled or locally sourced materials in construction. This reduces the transportation emissions associated with material sourcing and supports local economies.

- Optimizing wall design for stability and longevity to reduce the need for future interventions. A robust design minimizes the long-term environmental impacts associated with repair or replacement.

- Employing bio-retention systems or green walls to improve water management and biodiversity. This can involve incorporating native vegetation or green infrastructure elements into the design.

- Integrating the wall into the surrounding landscape. Blending the structure with the natural environment through careful landscaping and site preparation can minimize visual impact and enhance the site’s ecological value.

Environmentally Friendly Materials

Using environmentally friendly materials is an important aspect of sustainable construction. Examples include:

- Recycled concrete aggregates reduce the demand for virgin materials and divert waste from landfills.

- Geo-synthetics, such as geotextiles and geomembranes, can improve water management and reduce the need for extensive excavation.

- Bamboo or timber, which are renewable resources, can offer an alternative to traditional materials, but careful sourcing and appropriate treatment are critical.

Environmental Considerations

A comprehensive approach to environmental considerations is essential for responsible construction. These considerations should be integrated into all phases of the project:

- Design Phase: Thorough environmental impact assessments (EIAs) to identify potential ecological impacts, including habitat assessments, water resource evaluations, and species assessments. This step guides the project towards environmental responsibility.

- Construction Phase: Implementation of erosion control measures, noise and dust mitigation strategies, and strict adherence to waste management regulations. This minimizes disruption during the construction process.

- Operation Phase: Long-term monitoring of the wall’s performance and its impact on the environment. This ongoing assessment is critical to identify and address potential issues.

Safety Considerations

Railroad retaining walls, while crucial for infrastructure, present inherent safety risks. Proper design, construction, and maintenance protocols are paramount to mitigating these hazards and ensuring the safety of workers and the public. This section details the critical safety considerations associated with these structures.

Ensuring worker safety and preventing accidents during the lifecycle of a railroad retaining wall project is paramount. Comprehensive safety protocols, coupled with proactive risk assessment, are essential to minimize potential harm. Thorough planning and preparation are key components of a successful and safe project.

Design Safety Protocols

Careful design considerations minimize risks during construction and operation. Designers must account for anticipated soil pressures, seismic activity, and potential impacts from train movements. Precise calculations and material specifications are essential for structural integrity and safety. This includes incorporating appropriate safety factors in the design to account for unforeseen conditions or operational loads.

Construction Safety Protocols

Construction activities around railroad retaining walls necessitate strict adherence to safety regulations. Proper site preparation, equipment maintenance, and worker training are crucial. The use of appropriate personal protective equipment (PPE) and adherence to established safety procedures are critical. Establishing clear communication protocols between different teams involved in the construction process is vital to ensure a safe and efficient work environment.

Maintenance and Repair Safety Protocols

Regular maintenance and periodic repairs are essential for the long-term safety of railroad retaining walls. Pre-emptive maintenance can often avert larger, more hazardous repairs. Safety assessments, risk analysis, and updated safety protocols should be part of the maintenance plan. This includes proper planning, hazard identification, and implementing necessary safety precautions. For instance, the removal of unstable debris or structural elements must be undertaken with appropriate safety measures in place to prevent accidents.

Potential Hazards

Several hazards are associated with railroad retaining walls. These include: soil instability, material failures, and potential for collapse during construction or operation. Potential hazards associated with train movements near retaining walls, such as debris falling or impacting the structure, must be accounted for. Moreover, the presence of hazardous materials or substances in the surrounding area needs to be considered during design and construction.

Worker Safety Guidelines

Worker safety during construction activities requires a comprehensive approach. This includes:

- Providing thorough training on all safety procedures and protocols.

- Ensuring adequate supervision and adherence to safety regulations.

- Use appropriate personal protective equipment (PPE) such as hard hats, safety glasses, and high-visibility clothing.

- Implementing measures to control traffic and pedestrian access in work zones.

These guidelines aim to prevent accidents, injuries, and fatalities.

Emergency Response Plans

Developing comprehensive emergency response plans is critical for managing incidents and minimizing potential harm. The plan should Artikel procedures for dealing with accidents, including evacuation routes, contact information, and emergency response personnel. Regular drills and exercises help familiarize personnel with the plan and ensure preparedness.

Safety Hazards Related to Train Movements

Train movements near retaining walls pose specific safety hazards. These hazards include:

- Debris is falling from the trains or from the wall itself.

- Impacts from train movements.

- Potential for ground vibrations from train passage.

- The risk of fires or explosions, especially if hazardous materials are present.

Proper design and construction techniques are essential to mitigate these hazards and prevent accidents. Safety measures should consider the possibility of equipment failure and its effect on the stability of the wall.

Epilogue

In conclusion, designing and constructing railroad retaining walls requires a multifaceted approach, encompassing geotechnical analysis, structural design, and meticulous construction techniques. Careful consideration of environmental impacts, safety protocols, and long-term maintenance strategies is paramount. This discussion has highlighted the significance of these elements in ensuring the robustness and longevity of railway infrastructure. The successful execution of these projects often depends on the integration of these critical factors, demonstrating the significance of a well-planned and executed approach.