Standing Seam Corten A Comprehensive Guide

Standing seam corten roofing is a popular choice for modern structures, combining aesthetic appeal with impressive durability. Corten steel, known for its unique rust-like patina, offers a distinctive look that complements various architectural styles. This guide delves into the specifics of standing seam corten, exploring design considerations, installation procedures, and the long-term performance of this remarkable material.

From the initial design choices to the final installation, this guide covers every aspect of standing seam corten roofing. We’ll explore the material’s characteristics, including its distinctive appearance, weather resistance, and longevity. Moreover, we’ll compare corten steel to other roofing options, providing a comprehensive analysis of cost-effectiveness and environmental impact. The information presented aims to empower both architects and homeowners to make informed decisions about incorporating this exceptional roofing system into their projects.

Introduction to Standing Seam Corten

Source: pinimg.com

Standing seam metal roofing is a popular choice for its durability and aesthetic appeal. This type of roofing features overlapping metal panels, often in a “standing” or vertical configuration, creating a seamless and weather-resistant surface. This design minimizes gaps and reduces the risk of leaks. Corten steel, a specific type of weathering steel, is frequently used in standing seam roofing applications due to its unique properties.

Corten steel, through a controlled process, develops a protective, rust-like patina over time. This patina, a result of a complex oxidation process, creates a unique aesthetic and provides significant protection against further corrosion. The long-term stability and resilience of Corten steel are key advantages, making it an attractive choice for long-term roofing solutions.

Standing Seam Metal Roofing

Standing seam metal roofing is a type of roofing that uses interlocking metal panels in a vertical configuration. This design effectively seals the roof, minimizing gaps and reducing the risk of water penetration. The seams are typically mechanically fastened or bonded to ensure a strong and watertight connection. This construction method significantly contributes to the longevity and resilience of the roof structure.

Characteristics of Corten Steel

Corten steel is a unique type of weathering steel. It contains specific alloying elements that encourage a controlled oxidation process. This results in the formation of a self-healing rust-like patina that protects the underlying steel from further corrosion. This inherent characteristic makes it highly suitable for exterior applications like roofing, where long-term protection is critical. This process of developing a protective layer of corrosion products significantly extends the lifespan of the steel.

Advantages of Using Corten Steel for Standing Seam Roofing

- Enhanced Durability: The self-healing patina offers exceptional resistance to weathering and corrosion, extending the lifespan of the roof.

- Aesthetic Appeal: The natural, rust-like patina creates a distinctive and visually appealing aesthetic, often desired in modern architectural designs.

- Sustainable Choice: The long lifespan of Corten steel reduces the need for frequent replacements, minimizing waste and environmental impact.

- Excellent Weather Resistance: The protective patina provides a robust barrier against harsh weather conditions, including wind, rain, and snow.

Disadvantages of Using Corten Steel for Standing Seam Roofing

- Initial Cost: Corten steel typically has a higher upfront cost compared to other roofing materials like galvanized steel.

- Patina Variability: The color and texture of the patina can vary slightly depending on environmental conditions and exposure time, which might not be uniform across the entire roof surface.

- Potential for Staining: The patina can potentially stain surfaces if not properly managed or cleaned during construction.

- Limited Color Options: The inherent patina limits the design options in terms of pre-determined colors, as the aesthetic is based on the natural weathering process.

Typical Applications of Standing Seam Corten Roofing

Corten steel standing seam roofing is frequently used in commercial buildings, industrial structures, and agricultural facilities. Its durability and aesthetics make it suitable for a range of projects where longevity and a unique appearance are priorities. For example, warehouses, barns, and other large-scale structures often benefit from the long-term durability and cost-effectiveness of this roofing solution.

Comparison of Corten Steel with Other Roofing Materials

| Material | Advantages | Disadvantages |

|---|---|---|

| Corten Steel | High durability, unique aesthetic, self-healing patina, long lifespan | Higher initial cost, potential for patina variability, limited color options |

| Galvanized Steel | Affordable, readily available, and good corrosion resistance | Requires regular maintenance, less aesthetically diverse |

| Copper | Beautiful aesthetic, excellent durability, and high resale value | High initial cost, slow patina development, and requires specialized installation |

Design and Installation Considerations

Standing seam Corten steel roofing offers a compelling aesthetic and durability. However, achieving the best results requires careful consideration during the design and installation phases. Proper planning ensures longevity, structural integrity, and a visually appealing final product.

Design Options for Corten Roofing

Various design options are available for standing seam Corten roofing systems, allowing for customization to suit diverse architectural styles. These choices range from simple, single-slope designs to more complex multi-faceted configurations. Considerations include the roof’s pitch, the desired aesthetic, and the overall structural capacity of the building. Careful detailing of valleys, hips, and ridges is crucial for water management and aesthetic appeal. For instance, a steeper pitch might necessitate more intricate detailing to ensure proper water runoff, while a flatter pitch might demand more robust flashing to prevent water penetration.

Importance of Flashing and Sealant Application

Proper flashing and sealant application are paramount for protecting the Corten steel from corrosion and water damage. Flashing at intersections, penetrations, and around chimneys or vents is essential. High-quality sealant specifically designed for metal roofing should be used. The integrity of the flashing and sealant application directly impacts the roof’s lifespan and structural performance. Improper flashing can lead to leaks and premature corrosion, significantly reducing the roof’s service life. Furthermore, consistent sealant application helps prevent moisture intrusion, maintaining the structural integrity of the roofing system and the underlying building structure.

Critical Steps in Installing a Standing Seam Corten Roof

A meticulously executed installation is crucial for the longevity and performance of a standing seam Corten roof. Key steps include precise layout, accurate measurement, and careful handling of the steel panels. Proper support and bracing are essential for maintaining structural integrity, especially on larger roofs. Adherence to manufacturer specifications and local building codes is vital for a safe and compliant installation. Thorough quality control measures throughout the installation process are also vital.

Common Installation Procedures and Best Practices

- Careful alignment and layout are crucial for a uniform and aesthetically pleasing finish. Using precise tools and techniques is critical for achieving a professional-looking roof.

- Maintaining consistent panel spacing and securing each panel properly with appropriate fasteners is essential for structural integrity. This helps prevent sagging and other structural problems that can arise from improper installation.

- Thorough inspection of all seams, joints, and penetrations is necessary to ensure watertightness. This process helps to identify and address potential weaknesses or gaps in the system before installation is completed.

- Using appropriate safety equipment and following all relevant safety guidelines is critical to prevent accidents and injuries during the installation process. Implementing a safe working environment is paramount for worker well-being and project completion.

Fastener Types and Suitability for Corten Steel Roofing

Selecting the correct fasteners is crucial for the long-term performance of a Corten steel roof. Different fastener types offer varying degrees of strength and corrosion resistance.

| Fastener Type | Description | Suitability for Corten Steel |

|---|---|---|

| Stainless Steel Screws | Known for excellent corrosion resistance. | Excellent |

| Galvanized Steel Screws | Provides a good balance of cost and corrosion resistance. | Good, but stainless steel is often preferred for superior longevity. |

| Aluminum Screws | Lightweight and offers some corrosion resistance. | Suitable for specific applications, but stainless steel is usually the preferred choice for durability. |

| Zinc-Coated Screws | A more affordable option, but with limited corrosion resistance. | Generally not recommended for long-term use on Corten steel due to potential corrosion issues. |

A crucial factor to consider when choosing fasteners is the specific environmental conditions and the anticipated lifespan of the roof. Selecting the right fastener type ensures the longevity of the roof and maintains its structural integrity.

Aesthetics and Appearance

Corten steel roofing, renowned for its unique aesthetic qualities, offers a distinct visual appeal that evolves. Its inherent rust-like patina adds character and depth to any structure, making it a visually compelling choice for various architectural styles and landscaping contexts. The dynamic interplay of colors and textures contributes to the overall visual interest of the building.

Corten steel’s distinctive aesthetic arises from its inherent chemical reaction with the atmosphere. This process, known as patination, creates a visually captivating layer of rust-colored oxides on the steel’s surface. This rust, rather than being a flaw, is a defining characteristic that imparts a rich, aged, and textured appearance.

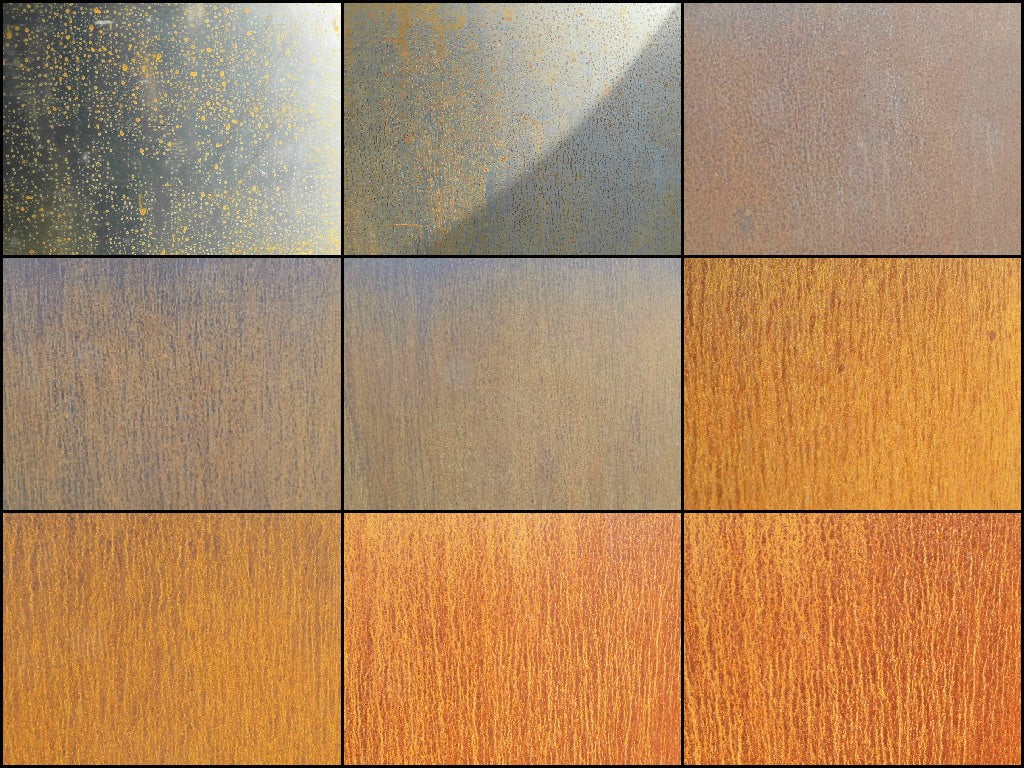

Patina Evolution

The patina of Corten steel is not static; it continuously develops and changes over time. The initial oxidation process typically involves the formation of a protective layer of rust, which gradually darkens and deepens in color as it ages. This evolution often results in a more nuanced and complex aesthetic, with variations in tone and texture emerging as the years pass.

Color Variations

Corten steel displays a wide spectrum of color variations, ranging from reddish-brown to deep burgundy and even greyish tones. The specific color outcome depends on several factors, including the steel’s composition, the local climate, and the amount of time it has been exposed to the elements. These variations in color and texture add a sense of dynamism and visual interest to the roofing system.

Visual Representations, Standing seam corten

Corten steel standing seam roofs can be integrated into a variety of architectural styles. For instance, a modern home might feature a sleek, minimalist roof with a subtle reddish-brown patina, enhancing the building’s contemporary aesthetic. A historical-style structure, conversely, might adopt a more pronounced, aged-copper tone to complement the building’s existing architectural details. Examples include residential buildings with gambrel or gable roofs, commercial structures with flat or pitched roofs, and even industrial buildings, where the material’s robustness and aesthetic appeal are highly valued.

Landscaping Integration

The aesthetic of Corten steel can effectively complement various landscaping contexts. The warm tones of the patina can seamlessly integrate with natural surroundings, like a wooded area or a rustic garden, enhancing the overall visual harmony. Conversely, the material’s distinct appearance can contrast beautifully with modern, minimalist landscaping, adding a striking element of visual interest. A contemporary garden design featuring geometric shapes and clean lines, for example, can be complemented by a Corten steel roof with a dark, mature patina. In a rural setting, a building with a Corten steel roof and exposed wooden beams creates a visually appealing contrast with the natural surroundings, seamlessly blending the building into the landscape.

Maintenance and Longevity

Standing seam Corten steel roofs, renowned for their aesthetic appeal and durability, require a carefully considered approach to maintenance to ensure their long-term performance. Proper care significantly extends the lifespan of these roofs, minimizing costly repairs and maximizing their value. This section delves into the maintenance strategies and the long-term performance characteristics of Corten steel.

Corten steel’s unique composition leads to a natural weathering process, developing a protective patina that shields the underlying metal from further corrosion. However, this natural process isn’t without its nuances, and understanding the factors influencing its effectiveness is crucial for proactive maintenance. Factors like environmental conditions, design considerations, and initial quality play a critical role in the longevity of a Corten steel roof.

Maintenance Requirements

A crucial aspect of Corten steel roof maintenance is understanding the natural weathering process. While the patina forms a protective layer, it can be influenced by various factors. Regular inspections are essential to identify any areas that are not developing the patina or where the existing patina is compromised.

Long-Term Performance Characteristics

Corten steel’s inherent corrosion resistance stems from its unique alloy composition. This alloy creates a self-healing, protective layer of rust (patina) that forms over time. This layer acts as a barrier against further corrosion, significantly extending the roof’s lifespan. However, the effectiveness of this protective layer is dependent on the exposure to environmental elements.

Corrosion Resistance and Durability

The durability of Corten steel is a direct result of its corrosion resistance. The self-healing patina provides a barrier against further corrosion, offering remarkable longevity compared to other metal roofing materials. However, factors like exposure to severe weather conditions, salt spray, or industrial pollution can accelerate the corrosion process, impacting the overall lifespan.

Factors Affecting Lifespan

Several factors can impact the lifespan of a Corten steel roof. These include the quality of the steel itself, the design of the roof system, and the environmental conditions. Proper installation and design minimize stress points and potential water damage, further enhancing the roof’s longevity. Also, geographic location and local weather patterns play a significant role in determining the pace of patina formation and potential corrosion issues.

Maintenance Strategies

Regular inspections and cleaning are crucial for maintaining the integrity of a Corten steel roof. A well-maintained Corten steel roof, which is regularly inspected and maintained, will perform exceptionally well over time. This proactive approach helps to prevent minor issues from escalating into significant problems.

| Maintenance Strategy | Frequency | Description |

|---|---|---|

| Visual Inspection | Quarterly | Inspect the entire roof for signs of damage, corrosion, or improper drainage. Look for areas lacking patina or showing signs of premature deterioration. |

| Cleaning (as needed) | Annually or as required | Remove debris, dirt, and accumulated materials that could hinder the natural weathering process. Use soft-bristled brushes or gentle pressure washing, avoiding harsh chemicals. |

| Repair (as needed) | As required | Address any identified damage promptly. Repair any penetrations, holes, or areas of significant corrosion. |

| Protective Coating (in specific cases) | As advised by professionals | In areas prone to accelerated corrosion, a protective coating may be considered. This is a decision best made by qualified professionals, considering factors like the severity of the issue and the location. |

Cost and Economic Factors

Corten steel, with its inherent durability and aesthetic appeal, presents a compelling case for roofing applications. However, understanding the associated costs is crucial for a sound financial decision. This section delves into the comparative pricing of Corten steel roofing versus other common materials, factors influencing project costs, long-term savings, and illustrative cost-benefit scenarios.

The initial cost of Corten steel roofing can sometimes be higher than alternatives like asphalt shingles or metal roofing made of galvanized steel. However, the long-term cost savings often outweigh the initial investment due to reduced maintenance and extended lifespan.

Comparison of Corten Steel Roofing Costs

A comparative analysis of Corten steel roofing costs reveals a nuanced picture. While upfront costs may be higher than some other options, the significant long-term savings from reduced maintenance and extended lifespan are key factors to consider.

- Asphalt Shingles: Often the most affordable option, asphalt shingles require frequent replacement, typically every 15-20 years. This recurring expense can add up over time, potentially exceeding the initial investment for Corten steel.

- Galvanized Steel Roofing: Often slightly less expensive than Corten initially, but galvanized steel roofing requires more frequent maintenance and may need replacement more often than Corten steel due to its lower resistance to corrosion. This can lead to higher long-term costs.

- Other Metal Roofing Options: Copper, zinc, and other metal roofing materials typically have higher upfront costs compared to Corten steel, often due to their rarity and higher manufacturing processes. However, these materials also have exceptional longevity, potentially leading to comparable long-term costs.

Factors Influencing Corten Steel Roofing Project Costs

Several factors influence the total cost of a Corten steel roofing project, including material costs, labor expenses, installation complexity, and site-specific requirements.

- Material Costs: The price of Corten steel can vary based on market fluctuations, the specific thickness of the steel, and the supplier. This is a crucial factor to consider during budgeting.

- Labor Costs: Installation complexity significantly impacts labor costs. A more intricate design or challenging site access can lead to higher installation costs.

- Project Size and Scope: Larger projects naturally involve greater material and labor requirements, leading to higher overall costs.

- Site Conditions: Factors like roof pitch, existing infrastructure, and access limitations can affect the complexity and cost of installation.

Long-Term Cost Savings of Corten Steel

Corten steel’s inherent durability translates into substantial long-term cost savings. The reduced maintenance requirements and extended lifespan directly contribute to the economic viability of this material.

- Reduced Maintenance: The inherent corrosion resistance of Corten steel means less need for repainting or repairs, significantly lowering ongoing maintenance costs.

- Extended Lifespan: A typical Corten steel roof can last 50-70 years or more, significantly exceeding the lifespan of alternative roofing materials.

- Decreased Replacement Costs: The prolonged lifespan of Corten steel leads to substantial savings over the long run, as fewer replacements are needed throughout its useful life.

Cost-Benefit Scenarios

The cost-benefit analysis of Corten steel roofing projects varies based on factors such as project size, regional material costs, and labor rates. However, in most cases, the long-term savings from reduced maintenance and extended lifespan outweigh the higher initial cost.

- Example 1: A 2,000 square foot residential roof using Corten steel, while more expensive upfront, shows significant cost savings over 50 years compared to asphalt shingle roofing. The reduced maintenance and extended lifespan lead to considerable long-term financial advantages.

- Example 2: A large commercial building’s roof, potentially saving thousands in maintenance over the decades, and the extended lifespan provides peace of mind. The initial investment in Corten steel is often recouped by the substantial cost savings over the long run.

Return on Investment (ROI)

The ROI of Corten steel roofing is highly dependent on project specifics, including the material cost, labor expenses, and project lifespan.

| Project Type | Estimated ROI (Years) | Factors Influencing ROI |

|---|---|---|

| Residential Roof (2,000 sq ft) | 10-15 | Material cost, labor rates, and maintenance frequency |

| Commercial Building (10,000 sq ft) | 7-12 | Project size, labor costs, and material prices |

| Industrial Facility (20,000 sq ft) | 5-10 | Installation complexity, maintenance schedule, and material cost |

Environmental Impact

Source: midmainemetal.com

Corten steel, with its unique rust-resistant properties, offers a compelling alternative in the construction industry. However, its environmental impact, from production to disposal, is a crucial factor in assessing its sustainability. Understanding this impact allows for informed decisions and the selection of environmentally responsible building materials.

The production of Corten steel, like all steel production, necessitates significant energy consumption. This energy often comes from fossil fuels, contributing to greenhouse gas emissions. Furthermore, the extraction and processing of raw materials required for steel production have environmental consequences, including habitat disruption and potential pollution. Consequently, a careful evaluation of the entire lifecycle of Corten steel is essential.

Corten Steel Production Impacts

The production of Corten steel involves several stages, each contributing to the overall environmental footprint. The extraction of iron ore and other raw materials requires substantial energy and can lead to land disturbance. Furthermore, the smelting and refining processes release greenhouse gases and other pollutants into the atmosphere. These emissions contribute to climate change and air quality issues. Minimizing these impacts necessitates careful consideration of energy efficiency and the adoption of cleaner technologies in the manufacturing process.

Comparison to Other Roofing Materials

Compared to other roofing materials, Corten steel exhibits a varied environmental footprint. Traditional asphalt shingles, for instance, often utilize petroleum-based products, leading to significant carbon emissions throughout their lifecycle. While some composite materials offer potential advantages in terms of resource consumption, their manufacturing processes may still have substantial environmental impacts. Assessing the entire lifecycle of each material, encompassing extraction, manufacturing, installation, and eventual disposal, is critical for a comprehensive comparison.

Recyclability of Corten Steel

Corten steel is highly recyclable. This characteristic is a significant advantage in terms of sustainability. The recycled steel retains its properties, reducing the need for virgin materials and minimizing the environmental impact of extraction and production. Existing recycling infrastructure for steel is well-established, making the process efficient and cost-effective.

Sustainable Building Practices with Corten Roofing

Numerous sustainable building practices incorporate Corten roofing. Utilizing recycled content in the steel production process is one example. Choosing local suppliers minimizes transportation-related emissions and supports regional economies. Furthermore, designing buildings with efficient insulation and natural ventilation reduces energy consumption, thereby lessening the environmental impact of the structure as a whole.

Carbon Footprint Comparison

| Roofing Material | Estimated Carbon Footprint (kg CO2e per square meter) | Notes |

|---|---|---|

| Corten Steel | ~500-700 | Depending on production methods and transportation distances. |

| Asphalt Shingles | ~800-1200 | Higher due to petroleum-based components. |

| Metal Tiles (Aluminum, Steel) | ~300-600 | Generally lower than asphalt, but it varies by production methods. |

| Clay Tiles | ~200-400 | Lower footprint due to natural material. |

This table provides a general comparison. The actual carbon footprint can vary considerably based on numerous factors, including manufacturing processes, transportation distances, and the specific composition of the materials.

Safety Considerations

Proper safety protocols are paramount during the installation of standing seam Corten steel roofs. Adhering to these guidelines protects workers, ensures the quality of the installation, and minimizes potential damage to the structure or surrounding environment. Thorough planning and meticulous execution are crucial to mitigating risks.

Safety Precautions During Installation

Implementing robust safety measures throughout the installation process is essential. This involves careful planning, pre-emptive risk assessments, and consistent adherence to established safety protocols. Pre-installation site surveys, which identify potential hazards, are critical to effective risk management. This includes identifying unstable ground conditions, overhead obstructions, and potential falls from heights.

- Fall Protection: All workers at heights must use appropriate fall protection systems, including harnesses, lanyards, and anchor points. Properly installed scaffolding and other elevated platforms should be used, ensuring their stability and adherence to local regulations. Regular inspections of these systems are crucial to maintain their effectiveness.

- Material Handling: Corten steel sheets are heavy. Use proper lifting equipment, such as cranes or hoists, for safe and efficient material handling. Ensure adequate support and prevent any slipping or dropping of materials during transport.

- Weather Considerations: Installation in adverse weather conditions, such as high winds or rain, requires specific safety precautions. Project scheduling should account for these factors, and work should cease during extreme weather events.

Safety Protocols for Working with Corten Steel

Corten steel, while durable, presents specific handling considerations. Understanding these protocols helps maintain a safe working environment.

- Sharp Edges: Corten steel sheets have sharp edges. Use appropriate protective gloves and safety glasses to avoid cuts and eye injuries. Covering sharp edges with protective tape is advisable.

- Welding Safety: Welding on Corten steel generates sparks and fumes. Appropriate ventilation, welding shields, and respiratory protection are essential. Welding procedures should comply with all relevant safety standards.

- Dust Control: Abrasive processes like cutting or grinding can generate dust. Appropriate dust control measures, including dust masks and ventilation systems, should be employed.

Potential Hazards and Mitigation

Recognizing potential hazards and implementing mitigation strategies are key to a safe installation.

- Electrocution: Ensure proper grounding of all electrical equipment to prevent electrocution hazards. Never work with electrical equipment near water or in damp conditions.

- Chemical Exposure: Corten steel can be exposed to various chemicals during fabrication or installation. Appropriate safety gear and handling procedures, including gloves and safety glasses, should be used to mitigate any chemical exposure.

- Noise Pollution: Certain tools and equipment generate considerable noise. Provide appropriate ear protection to prevent hearing damage.

Proper Safety Gear and Equipment

Choosing and using appropriate safety gear and equipment is critical for worker safety.

- Personal Protective Equipment (PPE): This includes safety glasses, hard hats, steel-toed boots, gloves, and respirators as needed. Regular inspection and maintenance of PPE are essential to ensure its effectiveness.

- Specialized Equipment: For tasks involving heights or heavy lifting, specialized equipment such as harnesses, ropes, and hoists is necessary. Their use should follow the manufacturer’s instructions and adhere to local safety regulations.

Safety Guidelines and Regulations

A comprehensive list of guidelines and regulations ensures adherence to best practices and local safety standards.

| Safety Guideline | Description |

|---|---|

| Fall Protection | All workers at heights must use appropriate fall protection systems. |

| Material Handling | Use proper lifting equipment and secure materials to prevent drops. |

| Weather Considerations | Schedule work to avoid extreme weather conditions. |

| Electrical Safety | Ensure proper grounding of electrical equipment and use insulated tools. |

| Chemical Handling | Use appropriate protective gear and follow chemical handling procedures. |

| Emergency Procedures | Establish clear emergency procedures and ensure readily available emergency equipment. |

Epilogue

In conclusion, standing seam corten roofing presents a compelling blend of aesthetics, durability, and sustainability. This comprehensive guide has illuminated the various facets of this material, from its distinctive patina to its economic viability. Ultimately, standing seam corten provides a robust and visually striking roofing solution, ideally suited for a range of architectural styles and applications. The detailed comparisons and practical insights presented will help you navigate the decision-making process with confidence.