Striated Metal Roof A Modern Architectural Choice

Striated metal roof, a modern architectural marvel, offers a striking blend of aesthetics and functionality. Its unique striations create a visually captivating surface, adding a touch of contemporary design to any structure. This roofing style is gaining popularity due to its diverse design options and performance characteristics.

From its intriguing visual appeal to its durable construction, striated metal roofs provide homeowners and architects with a compelling choice. This detailed exploration delves into the specifics of striated metal roofing, covering everything from material selection and installation to its environmental impact and cost-effectiveness.

Introduction to Striated Metal Roofs

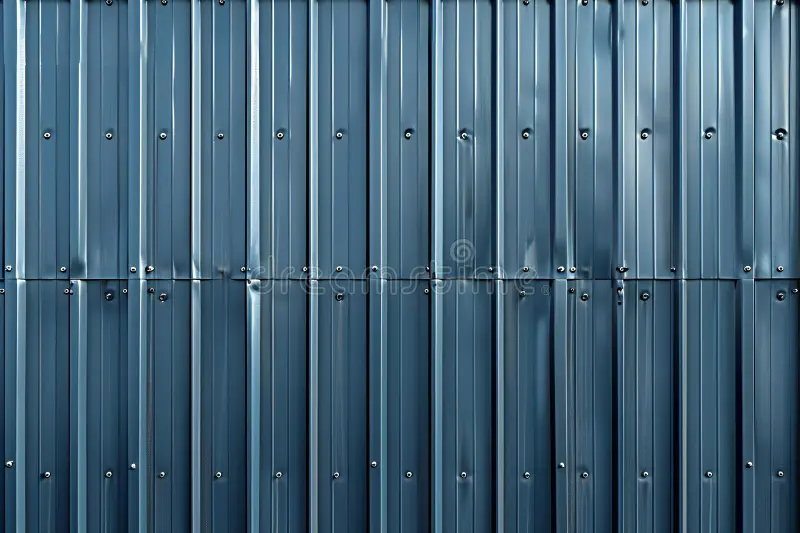

Striated metal roofing is a contemporary architectural element that brings a distinctive visual appeal to buildings. Characterized by its ribbed or grooved texture, it offers both aesthetic appeal and practical benefits. The unique striations, or linear patterns, create visual interest and can significantly alter the way a building appears, from a simple home to a large commercial structure.

Striated metal roofing distinguishes itself through its visually dynamic surface. The linear patterns of the striations add depth and dimension to the roof’s appearance, creating an eye-catching aesthetic that is both modern and sophisticated. This visual impact is often leveraged to complement or contrast with other architectural features, further enhancing the overall design.

Types of Striations

The design and depth of striations in metal roofing vary significantly. Different striation patterns can achieve distinct visual effects. Some examples include subtle, almost imperceptible grooves, while others feature pronounced ridges that create a more dramatic look. The choice of striation type is crucial in determining the overall aesthetic of the building.

Materials Used in Construction

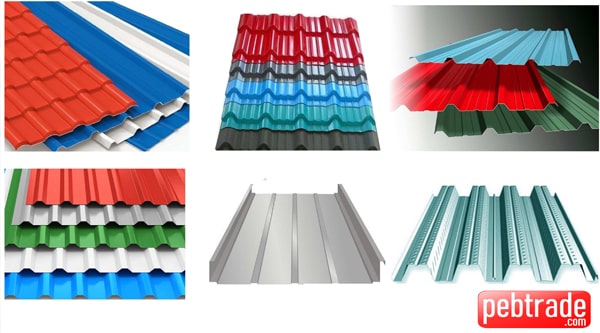

Various materials are employed in the construction of striated metal roofs, each with its own set of properties. Common materials include aluminum, steel, and copper. Aluminum is known for its lightweight nature and corrosion resistance, making it a popular choice for its cost-effectiveness. Steel, while heavier, provides greater strength and durability, particularly suitable for areas with high wind loads. Copper, with its unique aesthetic appeal and inherent corrosion resistance, is often chosen for its luxurious and enduring quality.

Architectural Styles

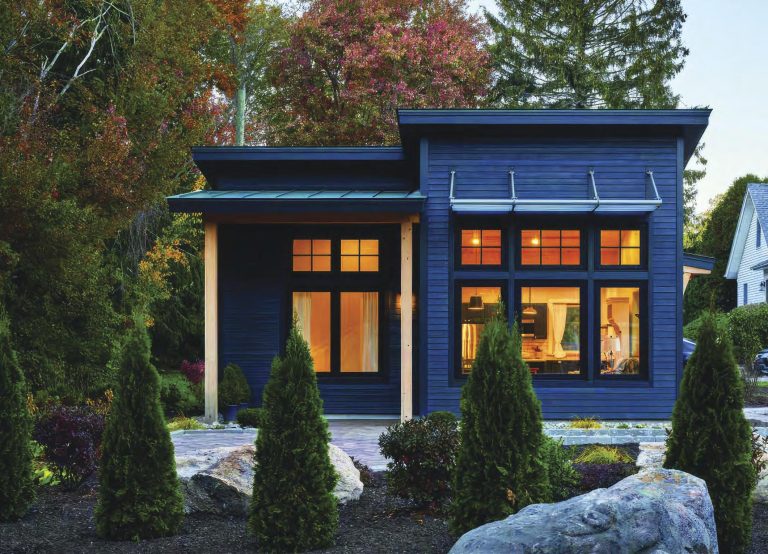

Striated metal roofing is often used in contemporary architectural styles, including modern, minimalist, and industrial designs. The linear patterns of striations can complement the clean lines and geometric forms frequently found in these styles. Striated metal roofs can also be integrated into more traditional designs, where the visual interest they provide can add a touch of modern flair without compromising the historical character of the structure. For instance, a historic farmhouse might benefit from the unique aesthetic of a striated metal roof while maintaining the architectural integrity of the existing design.

Examples of Styles that Utilize Striated Metal Roofs

- Modern architecture: Striated metal roofs often complement the clean lines and geometric forms frequently found in modern designs.

- Industrial architecture: The pronounced ridges of some striated metal roofing can effectively complement the raw aesthetic of industrial buildings, providing a strong contrast to the exposed materials.

- Contemporary homes: The visual interest offered by striated metal roofs can add a touch of modern flair to contemporary homes without compromising the overall design.

Performance and Functionality: Striated Metal Roof

Striated metal roofing, characterized by its distinctive ribbed or grooved surface, offers a compelling blend of aesthetic appeal and practical advantages. This design element significantly impacts the roofing’s performance in terms of durability, thermal efficiency, and water management. Understanding these aspects is crucial for homeowners and architects seeking a long-lasting and functional roofing solution.

Striated metal roofing’s performance is influenced by its inherent design. The grooves and ridges, often referred to as striations, create a unique structure that affects various aspects of the roof’s functionality. This detailed examination will delve into the specific ways these striations impact durability, lifespan, thermal properties, drainage, and visual appeal.

Durability and Lifespan, Striated metal roof

Striations, while adding visual interest, contribute to the overall durability of the metal roof. The increased surface area, provided by the striations, can contribute to enhanced longevity by allowing for better drainage and reducing the potential for water damage. Properly installed striated metal roofing, with appropriate materials and fasteners, can often match or exceed the lifespan of traditional roofing systems. Factors such as the type of metal used, the quality of the installation, and environmental conditions all play a role in determining the precise lifespan. For instance, a high-quality, well-maintained zinc roof might surpass 100 years.

Thermal Performance

Striations influence a metal roof’s thermal performance. The design can affect how the roof absorbs and radiates heat. While the exact impact varies based on the material and the specific striation pattern, studies show that properly designed striations can contribute to improved thermal efficiency, potentially lowering the building’s energy consumption for cooling and heating. This can be especially beneficial in climates with significant temperature fluctuations. For example, in hot climates, striations might help deflect sunlight and reduce the roof’s temperature, leading to less heat transfer into the building.

Water Runoff and Drainage

The striations act as channels, facilitating swift water runoff. This feature can significantly reduce the risk of water damage, which is a major concern for traditional roofing materials. The channels created by the striations ensure effective drainage, preventing water from pooling or stagnating. The angled design of the striations promotes water flow away from the roof surface, minimizing the risk of leaks and structural damage. This characteristic can be particularly important in regions prone to heavy rainfall or snowmelt.

Visual Appeal

Striations, beyond their functional benefits, contribute significantly to the aesthetic appeal of a roof. The patterns and designs offered by striations provide homeowners with options to customize the look of their property. The ribbed or grooved appearance can complement various architectural styles, adding a touch of contemporary or traditional design. Striations can create a visually appealing, dynamic surface that sets a roof apart from other roofing systems.

Installation and Maintenance

Source: davidkeeferoofing.com

Striated metal roofing, with its distinctive aesthetic and performance advantages, necessitates careful installation and ongoing maintenance for optimal longevity and performance. Proper procedures, along with the right tools and materials, are crucial to achieving a strong, watertight, and aesthetically pleasing roof. A well-maintained striated metal roof will not only withstand the elements but also enhance the value and curb appeal of a structure.

Installation Process

The installation of striated metal roofing involves a series of steps, each requiring precision and adherence to manufacturer specifications. Beginning with the proper site preparation, which includes the removal of the existing roof and ensuring a stable, level substrate, is paramount. Subsequent steps involve the installation of the necessary underlayment, flashing, and metal panels. Accurate panel alignment, proper fastening, and secure sealing are critical for a watertight roof.

Tools and Equipment

A comprehensive set of tools and equipment is essential for the successful installation of striated metal roofing. This includes, but is not limited to, specialized metal cutting tools, power tools such as drills and impact drivers, various measuring tools, safety equipment, and appropriate handling tools for the metal panels. A well-equipped workshop, or designated area, is critical to the efficiency of the installation process.

- Metal snips or shears for the precise cutting of metal sheets.

- Power drills with appropriate drill bits for fastening.

- Impact drivers for efficient fastening.

- Measuring tapes and levels for accurate alignment.

- Safety glasses and gloves for personal protection.

- Metal handling tools to prevent damage during transport.

- Roofing sealant and adhesives.

Cost Comparison

The installation cost of striated metal roofing can vary depending on factors like project size, complexity, labor costs, and material prices. A comparison to other roofing types reveals that while striated metal roofs might have a higher upfront cost, their long-term durability and low maintenance requirements often result in lower total cost of ownership over the life of the roof. Factors like regional differences in material costs and labor rates will also affect the final cost.

| Roofing Type | Typical Installation Cost (per square foot) |

|---|---|

| Asphalt shingles | $3-$6 |

| Tile roofs | $8-$15 |

| Metal roofing (various types) | $6-$12 |

| Striated Metal Roofing | $8-$14 |

Maintenance Requirements

Striated metal roofing, due to its inherent durability, has minimal maintenance requirements compared to other roofing materials. Regular inspections, however, are crucial for identifying any potential issues early on, such as loose fasteners, damaged panels, or signs of water intrusion.

Cleaning and Repair

Cleaning striated metal roofing involves removing loose debris and dirt. Gentle pressure washing is often sufficient, while more stubborn stains might require specialized cleaning agents. Repairing damaged panels typically involves replacing the damaged section with a new panel, ensuring a proper seal is achieved. It is essential to consult with a professional if significant repairs are needed. Repairing or replacing damaged panels is critical for maintaining the structural integrity and aesthetic appeal of the roof.

Design and Applications

Striated metal roofing, with its unique aesthetic and functional qualities, presents a versatile choice for a wide array of architectural styles and climates. This section explores various design options, applications across different architectural styles, and considerations for different climates. The specific design features and performance characteristics of striated metal roofs can significantly impact the overall aesthetic and practicality of a building.

Aesthetic Design Options

Striated metal roofs offer a range of aesthetic possibilities beyond the basic corrugated or flat profile. Varying the striation angle, width, and depth creates a spectrum of visual effects. A subtle, almost imperceptible striation can enhance a modern design, while a pronounced pattern can complement a more rustic or industrial aesthetic. Different metal finishes, from polished aluminum to weathered steel, further customize the visual impact.

Examples in Architectural Styles

Striated metal roofing can be seamlessly integrated into diverse architectural styles. In modern designs, the clean lines and subtle striations can provide a sophisticated touch. For industrial buildings, the bold striations and robust metal aesthetic can evoke a sense of strength and durability. The striated texture can also be incorporated into more traditional designs, where the pattern provides an intriguing contrast to historical elements.

Climate Zone Considerations

The effectiveness of striated metal roofing is influenced by the local climate. In regions with heavy snowfall, the striations can help with drainage, preventing water accumulation and potential damage. In hot, humid climates, the reflective properties of the metal can help reduce heat absorption, contributing to a more comfortable indoor environment. Proper consideration of local weather patterns and design details is crucial for optimal performance.

Residential and Commercial Applications: Pros and Cons

| Application | Pros | Cons |

|---|---|---|

| Residential Homes (Modern/Contemporary) | Visually striking, durable, potentially reduced cooling costs, and good drainage. | Higher initial cost compared to other roofing materials, potential for increased noise levels during rain, and less readily available in certain regional styles. |

| Residential Homes (Traditional/Rustic) | Aesthetic versatility, the ability to create visual interest in a variety of architectural styles. | It may not suit every architectural style, potential for increased maintenance compared to smooth metal roofing. |

| Commercial Buildings (Industrial) | Durable, strong visual statement, potentially lower maintenance compared to other materials. | Higher initial cost compared to other roofing materials, and potential for increased noise levels during rain. |

| Commercial Buildings (Retail/Office) | Aesthetic versatility, adaptable to various design styles, and potentially improved energy efficiency. | Requires careful design to ensure aesthetic compatibility with the surrounding architecture, more complex to install compared to other flat roofing options. |

Key Design Considerations

Selecting the optimal striated metal roof design requires careful consideration of several factors. The chosen striation pattern should complement the overall architectural style. The roof’s slope and drainage system are crucial for efficient water runoff. Proper flashing and sealant application are essential for preventing leaks and ensuring long-term performance. A thorough evaluation of local climate conditions and anticipated weather patterns should also be included.

Environmental Impact

Striated metal roofing, with its unique design and material properties, presents a compelling case for sustainable building practices. Its environmental impact is a multifaceted consideration, encompassing resource consumption, manufacturing processes, and the potential for recycling and energy efficiency. Understanding these factors is crucial for evaluating the overall ecological footprint of this roofing solution.

The manufacturing of any roofing material requires energy and resources. However, striated metal roofing, due to its inherent characteristics, can contribute positively to sustainability efforts, particularly through its recycling potential and energy efficiency features. The choice of raw materials and manufacturing processes directly influences the environmental footprint.

Recycling Potential

Striated metal roofing, being primarily composed of recycled or recyclable metal alloys, offers significant recycling potential. This inherent characteristic allows for the creation of a closed-loop system where the material can be reused multiple times, reducing the need for new raw material extraction. This process minimizes waste generation and conserves natural resources. Proper end-of-life management programs are essential for maximizing the recycling potential of striated metal roofs.

Energy Efficiency Characteristics

Striated metal roofing’s unique design can contribute to improved energy efficiency. The striations, or grooves, can enhance natural ventilation, potentially reducing the need for artificial cooling systems. This can translate into lower energy consumption and decreased carbon emissions associated with cooling systems. However, the exact energy efficiency gains depend on the specific design, climate conditions, and the overall building design.

Comparison of Environmental Impact

The environmental impact of striated metal roofing can be contrasted with traditional roofing materials. A comparative analysis should consider factors like embodied energy (energy used in material extraction, processing, and manufacturing), embodied carbon (carbon emissions associated with material production), and recyclability. The table below provides a simplified comparison, highlighting key distinctions.

| Roofing Material | Embodied Energy (MJ/m²) | Embodied Carbon (kg CO₂e/m²) | Recyclability |

|---|---|---|---|

| Striated Metal | 150-250 | 5-10 | High |

| Asphalt Shingles | 100-150 | 10-20 | Low |

| Clay Tiles | 200-300 | 15-25 | Medium |

| Slate | 250-400 | 20-30 | Medium |

*Note: Values are approximate and can vary based on specific material types and manufacturing processes.

Sourcing and Manufacturing Processes

The sourcing of raw materials for striated metal roofing is critical to its environmental profile. The use of recycled metal significantly reduces the environmental impact compared to using virgin materials. Manufacturing processes should prioritize energy efficiency and minimize waste generation. The use of sustainable manufacturing techniques, such as those that reduce water consumption or emissions, further contributes to a positive environmental impact. Furthermore, the manufacturing process itself should adhere to strict environmental regulations to minimize its footprint.

Visual Appeal and Aesthetics

Striated metal roofing, with its distinctive ribbed or grooved surface, offers a unique and compelling aesthetic that can significantly enhance the visual appeal of a building. The interplay of light and shadow across the surface creates dynamic visual interest, setting it apart from traditional flat or smooth metal roofing options. This visual appeal extends beyond mere aesthetics, influencing the overall architectural design and potentially impacting the occupants’ psychological response to the building.

The striated design, by its very nature, adds a textural element to the roof. This texture, combined with the reflective properties of metal, can produce various visual effects depending on the angle of sunlight and the specific striation pattern. The visual appeal of striated metal roofing is highly adaptable to diverse architectural styles.

Aesthetic Variations

The visual appeal of striated metal roofing is highly customizable. Different striation patterns, from subtle grooves to pronounced ridges, create distinct aesthetic characteristics. The depth and width of the striations significantly influence the overall visual impact, allowing for a wide spectrum of design possibilities. The choice of material and color further expands the design options, contributing to a building’s unique character.

Color Options

A wide array of color options is available for striated metal roofing, ranging from classic earthy tones to vibrant hues. The selection of colors can be tailored to match the surrounding environment or to create a striking contrast. Consideration should be given to the building’s architectural style and the desired aesthetic effect. For example, a deep charcoal gray might complement a modern structure, while a warm copper tone could blend harmoniously with a traditional farmhouse. The color choice can greatly influence the building’s perceived warmth, coolness, and overall visual personality.

Impact on Architectural Design

Striated metal roofing can significantly impact the architectural design of a building. The unique texture and visual characteristics of the striations can serve as a defining feature, adding a touch of modernism or a touch of rustic charm, depending on the design intent. The striations can accentuate the roofline’s contours and create a sense of dynamism. The material’s reflective qualities can also be strategically employed to direct light and shadow, creating visual interest and depth to the building’s facade. Examples include incorporating the striations into a building’s overall facade design to create a cohesive and visually appealing look.

Psychological Impact on Occupants

The visual appeal of striated metal roofing can have a subtle yet noticeable impact on the psychological well-being of building occupants. The interplay of light and shadow, the unique texture, and the overall visual interest can contribute to a sense of visual comfort and engagement. The reflective nature of the metal can also create a sense of spaciousness, particularly in smaller buildings, by reflecting surrounding light. The color palette chosen for the roofing material can further enhance the psychological experience, promoting feelings of calmness, energy, or excitement depending on the color scheme selected. A well-designed striated metal roof can evoke a positive response from those within the building, fostering a sense of visual harmony.

Cost and Budgeting

Striated metal roofing, while offering aesthetic appeal and enhanced performance, presents a spectrum of costs depending on various factors. Understanding the material costs, comparative pricing, and long-term financial implications is crucial for informed decision-making. This section delves into the financial aspects of incorporating this type of roofing.

Material Costs for Different Types

Different striated metal roofing materials, each with its unique composition and properties, contribute to varying costs. Aluminum, steel, and copper are common choices. Aluminum, often the most affordable option, is lightweight and readily available. Steel, while potentially more expensive than aluminum, often exhibits greater durability and resistance to corrosion. Copper, being the most costly, offers exceptional longevity, a rich aesthetic, and inherent antimicrobial properties. The cost of each material is directly related to its production and processing methods.

Cost Comparison with Other Roofing Types

A direct comparison between striated metal roofing and other materials like asphalt shingles, tile, or slate is necessary for effective cost analysis. Generally, striated metal roofing tends to fall within a mid-range price point, often outcompeting tile and slate while often being more expensive than asphalt shingles. However, the longer lifespan of striated metal roofs can make them a cost-effective choice in the long run. Specific costs will depend on local labor rates, material availability, and the particular striated metal roof design. For instance, a simple, aluminum striated metal roof in a residential area might cost less than a more complex, copper striated metal roof in a commercial setting.

Factors Affecting Final Cost

Several elements influence the overall cost of a striated metal roof installation. The size of the roof area significantly impacts material quantities and labor hours. The complexity of the design, including intricate patterns or custom shapes, also increases the overall cost. Local material availability, labor rates, and any necessary permits or inspections all contribute to the final price.

| Factor | Explanation |

|---|---|

| Roof Size | Larger roofs require more materials and labor, increasing costs. |

| Design Complexity | Custom designs or intricate patterns elevate material costs and labor time. |

| Material Type | Different metals (aluminum, steel, copper) have varying costs. |

| Installation Complexity | Roof pitch, access, and other site conditions impact installation costs. |

| Local Labor Rates | Regional labor costs affect the total installation expenses. |

| Permits and Inspections | Necessary approvals can add to the overall project cost. |

Financing Options

Numerous financing options are available for striated metal roof installations. These options include traditional mortgages, home improvement loans, or lines of credit. Many roofing contractors also offer financing options tailored to their clients’ specific needs. It’s crucial to compare interest rates, terms, and fees from different lenders to find the most advantageous financing package. The availability of special financing programs from roofing manufacturers or retailers may also exist.

Long-Term Cost-Effectiveness

The long-term cost-effectiveness of striated metal roofing stems from its extended lifespan, low maintenance requirements, and potential for increased property value. While the upfront cost might seem higher than other roofing materials, the reduced need for replacements over a longer period makes it a financially prudent choice in the long term. The reduced need for repairs and replacements translates into substantial savings over the roof’s expected lifetime, which can vary depending on the material and quality. Examples of long-term cost savings can be seen in case studies comparing striated metal roofs with other materials over decades.

Summary

Source: pinimg.com

In conclusion, striated metal roofs represent a significant advancement in roofing technology. Their striking aesthetics, combined with exceptional durability and performance, make them a compelling choice for both residential and commercial applications. While installation costs might be a factor, the long-term benefits and the unique visual appeal of striated metal roofing often outweigh these initial concerns. This comprehensive overview highlights the diverse aspects of this innovative roofing style, empowering informed decisions for those seeking a truly distinctive and modern architectural statement.