Striated Metal Roof Panels A Comprehensive Guide

Striated metal roof panels offer a compelling blend of aesthetics and performance. Their unique striation patterns create visually striking designs while maintaining excellent structural integrity and weather resistance. This guide explores the diverse aspects of these panels, from their design and manufacturing to their applications and cost-effectiveness.

This guide delves into the different types of striations, examining their impact on visual appeal, water runoff, and thermal performance. It also covers the various materials used in their creation, the intricacies of installation, and the overall sustainability of this innovative roofing solution. Furthermore, we’ll analyze cost factors, exploring the financial implications of choosing striated metal panels versus traditional roofing materials.

Introduction to Striated Metal Roof Panels

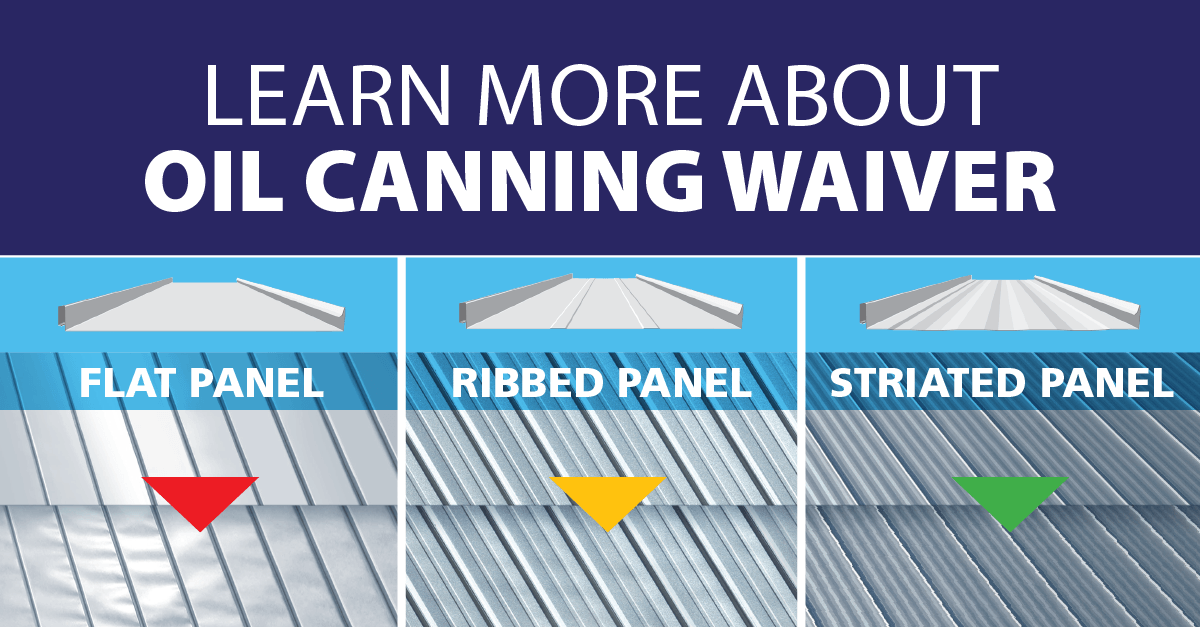

Striated metal roof panels offer a modern aesthetic and enhanced durability compared to traditional flat metal roofing. Their distinctive ribbed or grooved surface, known as striations, contributes to both visual appeal and functional benefits. This approach to metal roofing design has become increasingly popular due to its adaptability to diverse architectural styles and its ability to withstand challenging weather conditions.

Striations, or the patterns of raised lines on the metal surface, significantly impact the panel’s performance. They are designed to manage water runoff, improve structural integrity, and provide an aesthetically pleasing visual contrast. The specific design of these striations influences the overall appearance and functionality of the panel. Understanding the different types of striations and their implications is crucial for selecting the appropriate metal roof panel for a particular project.

Types of Striations

Various striation patterns are available in striated metal roof panels. These patterns vary in their depth, width, and spacing, leading to distinct visual effects. Common patterns include linear striations, which feature long, parallel lines; chevron striations, with a V-shaped pattern; and wave striations, resembling undulating lines. The choice of striation pattern influences the overall aesthetic appeal and the panel’s ability to manage water runoff.

Materials Used

Common materials used in the manufacturing of striated metal roof panels include galvanized steel, aluminum, and copper. Galvanized steel provides excellent corrosion resistance, while aluminum offers lightweight construction and superior durability. Copper, known for its aesthetic appeal and natural resistance to corrosion, is a more expensive option but is highly desirable for certain architectural designs. The selection of material is crucial, as it dictates the panel’s longevity, cost, and suitability for the specific environmental conditions.

Manufacturing Processes

The creation of striated metal roof panels involves specialized manufacturing techniques. These techniques often utilize pre-formed metal sheets or stamped designs to achieve the desired striation pattern. Modern methods involve sophisticated metal stamping, rolling, or embossing processes, ensuring the consistent quality and precision of the striated design. These processes also impact the panel’s final appearance and structural performance.

Panel Characteristics Table

| Panel Type | Material | Striation Pattern | Application |

|---|---|---|---|

| Standard Corrugated | Galvanized Steel | Linear | Residential and commercial roofing, often in industrial applications |

| Architectural Ribbed | Aluminum | Chevron | Modern architectural designs, where aesthetics are paramount |

| Rainscreen Panels | Aluminum or Copper | Wave | Contemporary roofing systems, where water management is critical |

| High-Tensile Steel | Galvanized Steel | Linear with Deep Grooves | Industrial buildings and structures, requiring high strength |

Design and Aesthetics of Striated Metal Roof Panels

Striated metal roof panels offer a compelling blend of functionality and aesthetic appeal. Their unique striation patterns, ranging from subtle grooves to pronounced ridges, create visual interest and can significantly impact the overall architectural design of a building. Understanding these design elements and aesthetic considerations is crucial for architects and homeowners alike in achieving a desired aesthetic outcome.

Striation patterns on metal roofing panels influence the way light interacts with the surface, creating a dynamic play of shadows and highlights. This visual effect can enhance the building’s character and contribute to its visual distinctiveness. The careful selection of striation patterns and colors can transform a simple roof into a striking architectural feature.

Striation Pattern Variations

The variety of striation patterns available in metal roof panels is vast. From subtle, almost imperceptible grooves, to pronounced, ridged textures, the design options are extensive. Some patterns mimic natural textures like wood grain or stone, while others are more abstract and contemporary. These variations can significantly alter the visual impact of the roof. A building with a roof featuring a finely striated pattern will likely project a different visual character compared to one with bold, pronounced striations.

Impact on Visual Appeal

The striation pattern significantly impacts the visual appeal of a building. A subtle striation pattern can add a touch of elegance and sophistication, while a bold pattern can create a dramatic and modern statement. The pattern’s depth and width play a crucial role in how the light interacts with the surface. Deep grooves will cast stronger shadows, while shallower striations will create a softer, more subtle effect. Careful consideration of the striation’s orientation about the sun’s path can also influence the visual appeal throughout the day.

Comparison to Other Metal Roofing Types

Compared to other metal roofing types, striated panels often offer a more textured and visually engaging surface. Smooth, plain metal roofs can appear flat and uninspired in comparison. Corrugated panels provide a different visual language, focusing on a repetitive pattern. The striation design provides a distinctive aesthetic alternative, allowing for a unique and personalized look. For instance, a building with a striated metal roof will have a different aesthetic appeal than one with a corrugated or flat metal roof.

Relationship between Striation Design and Architectural Style

The design of striation patterns can be effectively integrated with various architectural styles. A subtle striation pattern can complement a minimalist design, while a bold pattern can be a defining element in a contemporary structure. For example, a traditional farmhouse might look out of place with a highly modern striation pattern, while a contemporary building might embrace such a pattern.

Visual Impact Analysis

| Style | Striation Pattern | Color | Visual Impact |

|---|---|---|---|

| Contemporary | Bold, angular striations | Dark gray, charcoal black | Modern, dynamic, and striking |

| Traditional | Subtle, flowing striations | Muted earth tones, light gray | Elegant, sophisticated, and understated |

| Industrial | Wide, deep striations | Metallics, browns, or grays | Rustic, robust, and imposing |

| Mediterranean | Fine, horizontal striations | Warm terracotta, beige, or olive green | Inviting, warm, and inviting |

Performance and Functionality of Striated Metal Roof Panels

Striated metal roof panels, characterized by their distinctive grooved or ridged surface patterns, offer a unique blend of aesthetic appeal and functional benefits. Beyond their visually striking appearance, these panels demonstrate a robust performance profile, contributing significantly to the overall durability and longevity of the roofing system. This section delves into the performance characteristics of striated metal roofing, considering factors such as structural integrity, weather resistance, water management, lifespan, and thermal properties.

Impact on Structural Integrity

The striation patterns in metal roof panels, while aesthetically pleasing, also play a crucial role in enhancing structural integrity. The grooves and ridges act as reinforcement elements, increasing the panel’s load-bearing capacity. This structural reinforcement contributes to the overall strength and stability of the roofing system, enabling it to withstand heavier loads, such as significant snowfall or high winds. The precise design of the striations, including their depth and spacing, is a critical factor in optimizing this structural benefit. Thorough engineering analysis, often supported by computer modeling, ensures the panels can withstand the anticipated stresses in various environmental conditions.

Resistance to Weather Conditions

Striated metal panels demonstrate impressive resistance to a variety of weather conditions. Their robust construction and carefully engineered striations contribute to excellent wind resistance. The panels are designed to withstand high wind speeds, reducing the risk of damage or uplift. Furthermore, the panels are highly resistant to rain, snow, and hail, ensuring consistent protection against these elements. This resilience stems from the panels’ inherent strength, combined with the effective channeling of water created by the striations. Careful material selection and manufacturing processes further enhance the panels’ resistance to corrosion and degradation over time.

Effect on Water Runoff and Drainage

The striations in the metal panels effectively channel rainwater away from the roof surface. The grooved design directs water flow towards the gutters and downspouts, preventing water pooling and reducing the risk of leaks or damage to the roof structure. This efficient drainage system contributes to the overall longevity of the roof and minimizes the likelihood of water damage to the building’s interior. The optimized runoff is a crucial aspect of the panel’s performance, ensuring the longevity of the roof structure.

Lifespan and Maintenance Requirements

Striated metal panels, owing to their durable construction and resistance to corrosion, are known for their extended lifespan. Proper installation and regular maintenance are essential for maximizing the lifespan of these panels. Regular inspections and cleaning to remove debris can help maintain the optimal performance of the roof. With proper care, striated metal roofs can last for decades, requiring minimal maintenance. The longevity of these panels directly correlates with their resistance to corrosion and the effectiveness of the water management system.

Impact on Reflectivity and Thermal Performance

The striations can influence the panel’s reflectivity and thermal performance. The surface texture can either enhance or reduce solar radiation absorption. Striations, depending on their design, can alter the panel’s ability to reflect solar heat, potentially influencing the interior temperature of the building. The striations can also enhance the panel’s ability to reflect solar radiation, contributing to a more comfortable indoor environment. Factors like the panel’s color, the angle of sunlight, and the specific design of the striations all play a role in the overall thermal performance.

Analysis Table

| Weather Condition | Panel Response | Drainage | Maintenance |

|---|---|---|---|

| High Winds | Excellent resistance to uplift and damage | Water is effectively channeled away | Regular inspections for structural integrity |

| Heavy Rain | Water is directed away from the surface | An efficient drainage system prevents water from pooling | Cleaning to remove debris and ensure the gutters function properly |

| Snowfall | Robust enough to withstand heavy loads | Water and snow are effectively channeled away | Regular inspections to check for structural integrity |

| Hail | High resistance to damage from impact | Water is channeled away from the roof surface | Inspection for any damage to the panels |

Applications and Installation of Striated Metal Roof Panels

Source: kellyroofing.com

Striated metal roof panels, with their unique aesthetic and functional attributes, are finding increasing use in a variety of architectural settings. Their adaptability to different design styles and superior performance characteristics make them an attractive choice for both residential and commercial projects. This section delves into the diverse applications of these panels and the specifics of their installation.

The installation process of striated metal roof panels, while generally similar to traditional roofing methods, requires specific attention to detail and adherence to manufacturer guidelines. Proper installation is crucial to ensuring the longevity and performance of the roof system. Structural support and fastening methods play a vital role in the overall stability and durability of the finished roof.

Diverse Architectural Applications

Striated metal roof panels are suitable for a wide array of architectural styles, from contemporary to traditional. Their varied aesthetic qualities enable them to blend seamlessly into different surroundings. Applications range from single-family homes to large-scale commercial buildings, such as warehouses, retail spaces, and even public structures. The ability to customize panel colors and striation patterns enhances their adaptability to a wide spectrum of design concepts.

Installation Process Overview

Careful planning and preparation are paramount to a successful installation. This involves a thorough site assessment, considering the building’s structural support, and ensuring the availability of necessary tools and materials. Accurate measurements and detailed drawings are crucial to ensure precise panel placement. A thorough understanding of the manufacturer’s specifications is essential to achieving the best results.

Structural Support and Fastening

The structural support system for striated metal roofs needs careful consideration. The panels, though lightweight, must be securely fastened to the existing roof structure. This typically involves using specialized fasteners and ensuring proper spacing to maintain structural integrity. Engineers must consider wind load calculations and local building codes.

Comparison with Traditional Roofing Methods

Compared to traditional roofing materials like asphalt shingles or tiles, striated metal panels require a slightly different approach. The primary difference lies in the structural support and fastening systems. Metal panels often utilize a more intricate support framework. Proper adherence to manufacturer specifications is critical to ensure the long-term performance of the roof.

Installation Tools and Equipment

A range of tools and equipment are necessary for a professional installation. These include specialized metal cutters, drills, measuring tools, and appropriate safety equipment. Specific tools required for the installation of the striated panels may vary based on the panel’s type and the roof’s complexity. The use of proper safety equipment is paramount.

Installation Steps

- Site Preparation: This involves securing the roof structure, ensuring adequate ventilation, and assessing the structural support.

- Panel Measurement and Cutting: Accurate measurements are essential for precise panel placement and efficient use of materials. Cutting and shaping the panels to fit the roof structure is a crucial step.

- Support Structure Installation: The support framework, designed to accommodate the panels’ weight and ensure stability, must be installed correctly. This may include purlins, rafters, or other support elements.

- Panel Placement and Fastening: Striated panels are carefully positioned and securely fastened to the support structure, ensuring proper alignment and spacing.

- Final Inspection and Sealing: A thorough inspection is performed to ensure all panels are correctly installed and securely fastened. Any gaps or areas requiring additional sealing are addressed.

Cost and Sustainability of Striated Metal Roof Panels

Striated metal roof panels, with their unique aesthetic and potential for enhanced performance, represent a compelling alternative to traditional roofing materials. However, a crucial aspect of their adoption involves understanding their cost structure and environmental footprint. This section delves into the factors influencing the cost, comparing their cost-effectiveness to other options, and analyzing their sustainability profile.

The cost of striated metal roof panels is multifaceted, encompassing material acquisition, fabrication, installation, and potential labor costs. The specific price depends on factors like the metal type (e.g., steel, aluminum), panel size, complexity of the striation pattern, and geographic location. The cost-effectiveness of these panels will depend on the specific project requirements and local market conditions.

Factors Affecting Striated Metal Roof Panel Costs

Material costs vary significantly based on the chosen metal alloy. Aluminum, often favored for its lightweight properties, will usually command a higher price than steel. The intricacy of the striation design can also influence costs, with more complex patterns leading to higher manufacturing expenses. Transportation costs play a role, as they vary based on the panel’s origin and the distance to the installation site. Furthermore, the availability of skilled labor for installation can affect the overall cost, as labor rates can differ regionally.

Cost-Effectiveness Compared to Other Roofing Materials

Striated metal panels generally compete favorably with asphalt shingles, particularly in terms of longevity and potential for energy efficiency. However, initial material and installation costs may be higher than for some traditional materials, such as asphalt shingles. A detailed cost analysis should consider the total life-cycle costs, factoring in long-term maintenance and potential energy savings. For instance, in areas with high energy costs, the potential for reduced cooling and heating demands may offset higher initial costs over the panel’s lifespan. Comparing costs necessitates examining the specific project requirements and the regional market dynamics.

Environmental Impact of Manufacturing and Installation

The manufacturing process for striated metal panels involves energy consumption and potential emissions. The environmental impact of the process depends on the manufacturing facilities’ energy sources and waste management strategies. The installation phase can also have an impact through the transportation of materials and the potential for waste generation during the installation process. However, striated metal panels’ longevity often translates to reduced waste generation over the lifespan of a building compared to other roofing materials.

Recyclability of Striated Metal Panels, Striated Metal Roof Panels

Striated metal panels are generally highly recyclable, allowing for the recovery of valuable materials and reducing the need for virgin resources. The recyclability of the metal is often superior to that of some other roofing materials, such as asphalt shingles. Proper collection and processing procedures are essential to ensure that the recycling process is effective and environmentally responsible.

Comparative Analysis of Roofing Materials

| Material | Material Cost | Installation Cost | Environmental Impact | Sustainability |

|---|---|---|---|---|

| Asphalt Shingles | Low | Moderate | High (due to manufacturing process and disposal issues) | Low |

| Striated Metal Panels | Moderate to High | Moderate to High | Moderate (depending on manufacturing processes and recycling rates) | High (due to recyclability and longevity) |

| Clay Tiles | High | High | Low (generally) | Moderate |

| Slate | High | High | Moderate (depending on extraction and transportation) | Moderate to High |

Case Studies and Examples of Striated Metal Roof Panels

Striated metal roof panels, with their unique aesthetic and functional properties, are finding increasing application in diverse architectural projects. This section presents case studies of buildings incorporating these panels, highlighting the design considerations, challenges, and positive feedback associated with their use.

These case studies demonstrate the versatility of striated metal panels, showcasing their ability to enhance building aesthetics while maintaining performance and durability. Analyzing these projects provides valuable insight into the practical application and benefits of this evolving roofing material.

Commercial Building Application

Striated metal panels, with their textured surface and subtle striations, offer a modern and visually appealing alternative to traditional roofing materials. One prominent example is a retail plaza, where the panels were integrated into a contemporary design.

The striated metal panels on the retail plaza were chosen for their ability to create a striking visual presence while maintaining excellent weather resistance. The design aimed for a modern aesthetic with a textured finish, providing a unique and memorable architectural element. The panel’s subtle striations offer a visually appealing texture without overwhelming the building’s overall design. The panels were installed using standard techniques, and the construction process was relatively straightforward. Initial feedback has been overwhelmingly positive, with comments focusing on the building’s distinctive and aesthetically pleasing appearance.

Residential Building Integration

The use of striated metal panels in residential architecture is becoming increasingly popular. A notable example is a modern home featuring a sloped roof, where the panels effectively blend contemporary design with functionality.

The striated metal panels on the sloped-roof home were selected for their ability to provide a distinctive aesthetic while effectively managing rainwater runoff. The panels were integrated into the home’s design, creating a unique and visually appealing appearance. The striated design complements the home’s architectural style, adding depth and character. The installation process was completed without significant issues, and the home owners have expressed satisfaction with the panels’ performance and appearance.

Public Infrastructure Project

Striated metal panels are also finding their way into public infrastructure projects, where durability and aesthetic appeal are crucial considerations. A public library, for instance, used these panels to create a modern and welcoming exterior.

The striated metal panels on the public library were carefully chosen to create a modern and inviting aesthetic. The panels were selected based on their resistance to harsh weather conditions and their ability to maintain a high level of visual appeal over time. The installation process was carried out by experienced contractors, and the project team received positive feedback on the panels’ performance and durability. Initial reviews from community members and visitors have been very positive, emphasizing the striking visual appeal of the library’s exterior. The panels offer a contemporary aesthetic, creating a modern and welcoming architectural presence.

Future Trends and Innovations: Striated Metal Roof Panels

Source: roofhousepedia.com

Striated metal roof panels, with their unique aesthetic and functional properties, are poised for continued evolution. Emerging trends suggest a focus on enhanced sustainability, improved performance metrics, and novel design applications. The future of these panels likely hinges on advancements in materials, manufacturing processes, and innovative design solutions.

The architectural landscape is increasingly demanding sustainable and aesthetically pleasing building materials. Striated metal roof panels, already possessing a degree of aesthetic appeal, are likely to incorporate further design elements to meet evolving tastes and preferences. This includes not only subtle variations in striation patterns but also integration with other building materials and architectural styles.

Potential Design Trends

Future striated metal roof panel designs will likely emphasize customization and personalization. This will involve a broader spectrum of striation patterns, colors, and finishes, enabling architects and homeowners to create distinctive building facades. Moreover, integration with other architectural elements, such as solar panels or integrated lighting systems, will become more commonplace. This integration could enhance both the aesthetic appeal and functional capabilities of the building.

Emerging Technologies in Production

Advancements in 3D printing and laser cutting technologies will likely impact striated metal roof panel production. 3D printing could enable intricate and customized striation patterns, while laser cutting can enhance precision and efficiency in panel fabrication. These technologies promise reduced material waste, faster production times, and increased design flexibility. Further, the development of robotic automation in manufacturing processes could reduce labor costs and improve production quality.

New Materials and Manufacturing Techniques

The incorporation of lightweight yet durable composite materials in striated metal roof panels is anticipated. These composites could reduce the overall weight of the panels, facilitating easier installation and potentially reducing structural load demands. Further, the development of advanced coatings and finishes could enhance the panels’ resistance to corrosion, extend their lifespan, and provide enhanced color retention. Additionally, advancements in manufacturing techniques, such as powder coating or advanced anodizing, will improve the overall durability and aesthetics of the panels.

Future of the Striated Metal Roof Panel Market

The striated metal roof panel market is projected to experience steady growth driven by increasing demand for sustainable and aesthetically pleasing building materials. The incorporation of novel design elements and the integration of emerging technologies will further bolster this growth. Specific market segments, such as the green building sector, are likely to drive demand due to the panels’ inherent sustainability characteristics. Furthermore, the market is likely to see an increase in demand from regions with stringent building codes requiring sustainable materials, thus broadening the potential application areas for these panels. The growing popularity of modular construction also presents an opportunity for the wider use of striated metal panels. For instance, prefabricated building components featuring striated metal roofing could gain traction in various markets, particularly for residential and commercial construction.

Conclusive Thoughts

In conclusion, striated metal roof panels represent a significant advancement in roofing technology. Their unique combination of visual appeal, performance characteristics, and potential cost-effectiveness makes them an attractive option for diverse architectural applications. While the initial cost may be a consideration, the long-term benefits, including enhanced aesthetics, improved weather resistance, and potential sustainability advantages, warrant further investigation. This guide has provided a comprehensive overview of these innovative panels, equipping readers with the knowledge necessary to make informed decisions regarding their use.