Striated Standing Seam Metal Roof Design & Performance

Striated standing seam metal roof offers a unique blend of aesthetics and performance, standing out from traditional roofing solutions. Its visually engaging striations, available in various patterns, create a distinctive architectural element, while its durability and weather resistance ensure long-term protection.

This comprehensive guide explores the design, installation, and performance characteristics of striated standing seam metal roofs, examining their advantages, potential costs, and environmental impact. From the manufacturing process to practical maintenance tips, we’ll delve into every aspect of this innovative roofing choice.

Overview of Striated Standing Seam Metal Roofs

Source: pinimg.com

Striated standing seam metal roofs offer a visually appealing and durable alternative to traditional standing seam roofs. Their unique aesthetic, achieved through a variety of striation patterns, adds character and depth to any building’s exterior. Beyond the aesthetic, striations can also subtly enhance the roof’s performance characteristics, contributing to its longevity and resilience.

Striated standing seam metal roofing is a modern take on a classic material. By incorporating patterns of raised or indented lines, called striations, manufacturers can achieve a wide range of visual effects, making the roof more architecturally interesting. This visual impact is often complemented by enhanced durability and weather resistance, characteristics often associated with high-quality metal roofing.

Aesthetic Characteristics and Visual Appeal, Striated standing seam metal roof

Striations on standing-seam metal roofs provide a captivating visual element. The patterns create a sense of texture and movement, drawing the eye and adding visual interest to the building’s profile. The degree of striation depth and direction significantly impacts the overall aesthetic. For instance, subtle striations can create a refined look, while more pronounced striations can evoke a bold and modern aesthetic.

Examples of Different Striation Patterns and Their Visual Effects

Various striation patterns are available, each producing a distinct visual effect. A common pattern is the linear striation, which creates a subtle, flowing design. Another approach involves a series of parallel, raised lines, producing a more pronounced, almost ribbed effect. Diagonal striations can provide a dynamic, angular look, while curved striations can evoke a more organic and flowing aesthetic. The choice of pattern often depends on the architectural style of the building and the desired visual impact.

Manufacturing Process and Materials Used

The manufacturing process for striated standing seam metal roofs is largely similar to that of traditional standing seam roofs. High-quality steel or aluminum sheets are used as the primary material, often coated with protective finishes to prevent corrosion. The striations are incorporated during the rolling or stamping process, ensuring a consistent and precise pattern throughout the roof panel. The precise manufacturing process ensures durability and longevity, contributing to the long-term value of the roof.

Comparison to Traditional Standing Seam Roofs

Traditional standing seam metal roofs are simpler in design, typically featuring a smooth surface without striations. Striated roofs, in contrast, offer a more pronounced visual impact. The striations can subtly enhance the roof’s performance, though this enhancement is often minimal compared to other factors like the material itself and the quality of the installation. The decision to opt for striated roofing often comes down to aesthetic preference and the desired architectural style.

Key Differences Between Striated Patterns

| Striation Pattern | Visual Effect | Potential Applications |

|---|---|---|

| Linear | Subtle, flowing lines | Modern, contemporary, or traditional styles |

| Parallel Raised Lines | Pronounced, ribbed appearance | Industrial, modern, or bold architectural designs |

| Diagonal | Dynamic, angular look | Contemporary or industrial styles, where a more dynamic look is desired |

| Curved | Organic, flowing appearance | Architectural styles that emphasize curves or organic shapes |

Striated patterns can dramatically influence the aesthetic of a metal roof. The table above highlights the key distinctions between these patterns, offering insights into their visual characteristics and potential applications. This table provides a quick reference guide for architects and homeowners considering this roofing option.

Benefits and Advantages

Source: kentuckymetalroofing.com

Striated standing seam metal roofs offer a compelling blend of aesthetic appeal and practical advantages. Their distinctive design, combined with advanced manufacturing techniques, enhances performance characteristics, potentially leading to significant cost savings and reduced long-term maintenance. This section explores the key benefits, focusing on durability, weather resistance, energy efficiency, and cost-effectiveness.

The unique striations, or grooves, on the metal panels contribute to improved water shedding, reducing the risk of leaks and water damage. Furthermore, the robust construction of these roofs often translates to superior durability compared to traditional roofing materials.

Durability and Weather Resistance

Striated standing seam metal roofs exhibit exceptional durability due to the robust construction methods and the high-quality metal used in their fabrication. The standing seam design, with its interlocking nature, creates a seamless and weather-tight barrier against wind and rain. The striations further enhance the roof’s water-shedding capabilities, minimizing the risk of water pooling and subsequent damage. This feature significantly contributes to the roof’s overall longevity and weather resistance. The material’s inherent resistance to corrosion and degradation, particularly when properly coated, ensures a long lifespan.

Energy Efficiency

The reflective properties of metal roofing materials, including striated standing seam, can play a significant role in energy efficiency. Darker roofing materials absorb more solar radiation, leading to higher building temperatures. Striated standing seam metal roofs, especially those with specialized coatings or finishes, can reflect a substantial portion of solar heat, reducing the heat load on the building. This effect contributes to lower cooling costs, making these roofs particularly beneficial in hot climates. The reduced heat transfer also minimizes the need for air conditioning, leading to lower energy consumption and reduced carbon footprint.

Applications

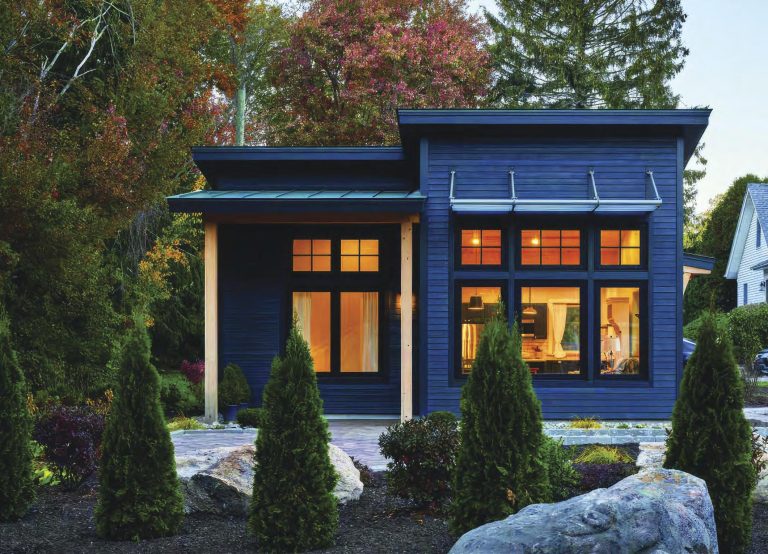

Striated standing-seam metal roofs are well-suited for a variety of applications. Their modern aesthetic and durability make them suitable for residential homes, commercial buildings, and industrial structures. The design’s flexibility in customization allows for various architectural styles. Examples include new construction projects seeking a contemporary look or renovations aimed at upgrading existing buildings. The versatility of this type of roof extends to different climate zones.

Cost-Effectiveness

The initial investment in a striated standing seam metal roof might seem higher compared to some other roofing materials. However, the long lifespan and reduced maintenance needs often translate into cost-effectiveness over the roof’s entire lifespan. Lower maintenance costs, coupled with potential energy savings, can offset the initial investment. Comparative analyses of long-term costs for various roofing types are available.

Maintenance Requirements

Striated standing-seam metal roofs require minimal maintenance compared to other roofing options. Regular inspections and occasional cleaning are typically sufficient. The inherent durability of the material reduces the need for frequent repairs or replacements. The smooth surface design minimizes the accumulation of debris, simplifying cleaning procedures. Routine maintenance, such as inspecting for loose fasteners and potential damage, can be performed by qualified professionals or DIY enthusiasts with basic tools.

Comparison of Roofing Materials

| Roofing Material | Lifespan (Years) | Maintenance Needs |

|---|---|---|

| Asphalt Shingles | 15-30 | Moderate (e.g., regular inspections, occasional repairs) |

| Tile Roofing | 50-100 | Low to moderate (e.g., occasional cleaning, repairs) |

| Metal Roofing (including Striated Standing Seam) | 50-75+ | Low (e.g., regular inspections, occasional cleaning) |

| Wood Shake Roofing | 20-40 | Moderate to High (e.g., regular inspections, repairs, maintenance) |

This table provides a general comparison. Actual lifespan and maintenance requirements can vary based on specific installation practices, environmental factors, and the quality of materials.

Installation and Application

Striated standing seam metal roofs, with their unique aesthetic and robust design, require a meticulous installation process. Proper installation ensures the longevity, structural integrity, and weather resistance of the roof system. Adhering to precise techniques and using appropriate tools is critical for a successful outcome.

The installation process for striated standing seam metal roofs involves several key steps, from initial preparation to final sealing. Understanding these steps and the necessary tools is essential for achieving a quality installation. Careful consideration of different roof designs and varying installation scenarios is also crucial for optimal results.

Installation Steps

The installation process generally follows a sequence of steps. First, the supporting structure, often a metal deck, needs to be prepared. This preparation ensures a level and secure base for the metal panels. After that, the panels are carefully positioned and fastened, with precise alignment critical to avoid leaks or structural issues. A comprehensive quality control check is then necessary to guarantee a watertight seal and secure attachment of each panel.

Tools and Equipment

A comprehensive set of tools and equipment is required for a professional striated standing seam metal roof installation. These tools include, but are not limited to, specialized metal roofing tools, measuring and marking instruments, power tools, safety equipment, and fastening components. The precise tools needed will vary based on the specific design of the roof and the complexity of the installation.

- Metal Roofing Tools: These tools include specialized snips, rivet guns, and seam rollers for manipulating the metal and ensuring a tight seal. The precise types will depend on the particular metal and fastening system.

- Measuring and Marking Instruments: Accurate measurements are essential for proper alignment and panel placement. Tools like measuring tapes, levels, and marking pens are necessary for this step.

- Power Tools: Power tools, such as drills and saws, can accelerate the installation process. Appropriate power tools will depend on the material being worked with and the complexity of the installation.

- Fastening Components: The fasteners themselves, including screws, rivets, and sealant, are critical for the longevity and water resistance of the roof. Selecting the appropriate fasteners is essential to withstand the elements and maintain the integrity of the structure.

- Safety Equipment: Safety is paramount during any roof installation. This includes appropriate fall protection gear and personal protective equipment (PPE) such as safety glasses and hard hats.

Installation Procedure

A comprehensive installation procedure ensures the integrity and longevity of the roof. This includes proper panel alignment, fastening techniques, and quality control checks.

- Preparation: Thorough preparation of the substrate, including the metal deck or other structural support, is crucial for a secure and watertight installation. This involves checking for any imperfections and ensuring a level surface.

- Panel Placement: Precise panel placement and alignment are vital to prevent leaks and maintain the aesthetic appeal of the striated standing seam design. Care must be taken to ensure proper overlap and alignment.

- Fastening: Using appropriate fasteners, ensuring proper tightness, and maintaining consistent spacing between fasteners is key to long-term roof integrity. Following the manufacturer’s recommendations is important.

- Seaming and Sealing: Seaming and sealing are critical for watertightness. Using appropriate tools and techniques for creating watertight seams is essential to prevent leaks.

- Inspection and Quality Control: Thorough inspections during and after installation are necessary to catch any potential issues early. Checking for proper alignment, secure fastening, and watertight seals is essential.

Comparison of Installation Methods

Different striated standing seam roof designs may have variations in installation methods. Factors such as the complexity of the roof’s shape, the specific metal used, and the fastening system will influence the installation approach. Some designs might involve specialized tools or techniques to ensure the unique features of the roof are properly implemented.

Fastener Types

Selecting the correct fasteners is essential for a durable and watertight installation.

| Fastener Type | Description | Suitability |

|---|---|---|

| Rivets | Permanently join metal sheets. | Suitable for high-strength applications. |

| Screws | Allow for adjustment and removal. | Suitable for areas requiring flexibility. |

| Sealant | Provides a waterproof barrier. | Essential for ensuring watertightness. |

Installation Scenarios

Installation scenarios vary greatly, from simple sloped roofs to complex structures. The installation process for a sloped roof generally involves laying panels according to the roof pitch, ensuring proper overlap and fastening. Complex roofs, like those with multiple valleys or unusual shapes, require more careful planning and specialized techniques.

Design Considerations and Variations

Striated standing seam metal roofs offer a compelling blend of aesthetic appeal and practical benefits. Careful design considerations are crucial to maximizing these advantages and achieving a visually striking and durable final product. Understanding the impact of striation patterns, architectural integration, and climate-specific factors is paramount.

Striation patterns, the series of grooves or ridges on the metal surface, significantly affect the visual character of the roof. The choice of striation pattern is a critical design element, directly influencing the aesthetic appeal and overall architectural expression of the building. Different patterns evoke various moods and styles, from sleek and modern to rustic and traditional.

Striation Pattern Impact on Aesthetics

The arrangement and depth of striations can dramatically alter the visual perception of the roof. A subtle, closely spaced pattern can create a refined and sophisticated look, while a bolder, wider pattern might lend a more rugged and industrial aesthetic. Careful consideration of the building’s architectural style is vital in selecting the appropriate striation pattern. The pattern should complement and enhance the existing design elements, rather than clashing with them. For example, a modern, minimalist building might benefit from a smooth, almost imperceptible striation, while a farmhouse or barn might embrace a more pronounced and textured pattern.

Architectural Integration

Integrating a striated standing seam roof into a variety of architectural styles is possible. The versatility of the material allows for its adaptation to different aesthetic preferences. The design should maintain consistency with the overall design principles of the building. For example, a striated metal roof with a dramatic, angular design would be more fitting on a contemporary structure than a historic building.

Climate Zone and Roof Orientation Considerations

Different climate zones and roof orientations present unique challenges and opportunities. Proper ventilation is essential in all situations, but especially in regions with high humidity or heat. In regions with high snowfall, the design must account for snow accumulation and runoff. The orientation of the roof, north-south versus east-west, impacts solar exposure and heat gain. Consideration of wind patterns is also crucial, as different patterns will affect the performance and durability of the striated seams. This is particularly true for high-wind zones.

Ventilation Considerations

Proper ventilation is paramount for any metal roof, especially striated ones. The striations can potentially trap heat and moisture, leading to issues like corrosion and reduced lifespan. A well-ventilated roof will maintain a healthy environment, preventing the build-up of humidity and temperature differences that could damage the metal over time. Adequate ventilation systems, including ridge vents, soffit vents, and underlayment options, should be incorporated to facilitate proper air circulation.

Striation Pattern Comparison

| Striation Pattern | Visual Appearance |

|---|---|

| Fine, closely spaced | Refined, sophisticated, subtle |

| Moderate, medium spacing | Balanced, versatile, adaptable |

| Bold, wide spacing | Rustic, industrial, dramatic |

| Diagonal | Modern, dynamic, angular |

| Vertical | Formal, structured, classic |

Maintenance and Repair

Striated standing seam metal roofs, while durable, require proactive maintenance to ensure longevity and optimal performance. Proper care minimizes potential issues and reduces costly repairs down the line. This section details the recommended maintenance schedule, common tasks, repair options, and potential problems for these roofs.

Regular inspection and upkeep are crucial for preventing deterioration and extending the lifespan of a striated standing seam metal roof. A well-maintained roof not only protects the building but also contributes to energy efficiency and a positive aesthetic.

Maintenance Schedule and Procedures

A proactive maintenance schedule is key to maintaining the integrity of a striated standing seam metal roof. A visual inspection should be performed at least twice a year, ideally after significant weather events (heavy rain, snow, high winds). This initial assessment should include checking for any signs of damage, such as dents, punctures, or loose fasteners. Thorough cleaning should also be part of the maintenance routine.

Common Maintenance Tasks and Best Practices

Regular cleaning is essential for preventing debris buildup and maintaining the roof’s appearance. This involves removing leaves, twigs, and other debris from the seams and valleys. Cleaning should be done using a soft-bristled brush or a low-pressure water spray to avoid damaging the metal surface. Inspecting the flashing and sealant areas is also critical to prevent water leakage.

Repair Options for Damaged or Deteriorated Sections

When damage occurs, prompt action is vital. Minor dents or scratches can often be repaired using specialized metal repair compounds or touch-up paint. For more extensive damage, professional repair is recommended. This may involve replacing damaged sections of the standing seam or addressing leaks from flashing or sealant issues.

Potential Issues During the Roof’s Lifespan

Over time, the striated standing seam metal roof may experience issues like corrosion, especially in areas exposed to salt spray or high humidity. Loose fasteners or damaged sealant can also lead to leaks. Proper maintenance and timely repairs can help prevent these problems.

Examples of Different Repair Techniques for Striated Standing Seam Roofs

Various repair techniques are available depending on the severity of the damage. For small dents, a metal repair compound, followed by touch-up paint, is often sufficient. If the damage involves a section of the seam, specialized tools and techniques are required for proper repair and sealing. Damaged flashing should be replaced with appropriate materials and the sealant reapplied for watertight protection.

Table of Common Maintenance Issues and Solutions

| Maintenance Issue | Solutions |

|---|---|

| Loose fasteners | Tighten or replace fasteners as needed. |

| Debris accumulation | Regular cleaning with a soft brush or a low-pressure water spray. |

| Minor dents | Metal repair compound and touch-up paint. |

| Flashing damage | Replace damaged flashing and reapply sealant. |

| Corrosion | Address the source of corrosion (e.g., humidity, salt spray) and apply appropriate protective coatings. |

Environmental Impact

Striated standing seam metal roofs offer a compelling choice for environmentally conscious building projects. Their material composition, sourcing practices, and recyclability contribute to a reduced carbon footprint compared to traditional roofing materials. The inherent durability of metal roofs, coupled with their efficient energy performance, further enhances their environmental appeal.

The environmental impact of a building’s roof extends beyond the material itself, encompassing the manufacturing process, transportation, and eventual disposal. Striated standing seam metal roofs, with their inherent properties, offer a promising path towards sustainable building practices. This section will delve into the various facets of this environmental impact, from material sourcing to recycling and energy efficiency.

Material Sourcing and Sustainability

Sustainable sourcing of raw materials is crucial for minimizing the environmental impact of any construction material. Striated standing-seam metal roofs often utilize recycled steel, significantly reducing the need for virgin ore extraction. This reuse of existing materials decreases energy consumption and associated emissions compared to producing steel from raw materials. Moreover, manufacturers committed to sustainable practices often source materials from ethically managed mines, prioritizing responsible resource extraction.

Environmentally Friendly Manufacturing Processes

Many metal roofing manufacturers are adopting environmentally friendly manufacturing processes. These include reducing water usage, minimizing waste generation, and utilizing energy-efficient technologies in the production process. Examples of such practices include the implementation of closed-loop systems for waste management and the use of renewable energy sources like solar power to operate manufacturing facilities.

Recyclability of the Material

Striated standing-seam metal roofs are highly recyclable. The metal used in these roofs can be collected and processed into new products, effectively closing the loop on material usage. The recycling process requires significantly less energy than the production of new steel from raw materials, thus further reducing the environmental impact. This inherent recyclability makes metal roofing a sustainable choice for long-term building projects.

Energy Efficiency and Reduced Environmental Impact

The reflective properties of metal roofing, particularly in the striated standing seam design, contribute to energy efficiency. The roof reflects a substantial portion of solar radiation, reducing the heat absorbed by the building. This translates to reduced reliance on air conditioning, resulting in lower energy consumption and decreased greenhouse gas emissions. Studies have shown that properly designed metal roofs can significantly reduce cooling loads in buildings, lowering their overall environmental impact.

Comparison of Environmental Impact of Roofing Materials

| Roofing Material | Material Sourcing | Manufacturing Process | Recyclability | Energy Efficiency | Overall Environmental Impact |

|---|---|---|---|---|---|

| Striated Standing Seam Metal | Recycled steel, ethically sourced | Energy-efficient, low-waste | Highly recyclable | High reflectivity reduces cooling load | Low |

| Asphalt Shingles | Fossil fuels | High energy consumption | Low recyclability | Low reflectivity, high heat absorption | High |

| Clay Tiles | Clay extraction | Energy intensive | Low recyclability | Moderate reflectivity, moderate heat absorption | Medium |

| Concrete Tiles | Cement production (high energy) | Energy intensive | Low recyclability | Moderate reflectivity, moderate heat absorption | Medium-High |

Note: This table provides a general comparison. Specific environmental impacts can vary based on individual product specifications, manufacturing processes, and regional factors.

Case Studies and Examples: Striated Standing Seam Metal Roof

Striated standing seam metal roofs are gaining popularity for their aesthetic appeal and practical benefits. Real-world projects offer valuable insights into the design considerations, challenges, and outcomes associated with this roofing type. This section presents case studies showcasing the application of striated standing seam metal roofs, highlighting their specific design features and performance characteristics.

Project 1: The Modern Farmhouse

This project involved a contemporary farmhouse with a large, sloped roof. The design team opted for a striated pattern that subtly echoed the architectural lines of the building, creating a sophisticated and visually appealing aesthetic. The striations were designed to minimize water runoff while maximizing the visual impact. The specific striation pattern was a series of vertical lines, slightly offset, to create a sense of movement and depth. The aesthetic impact was one of modern elegance, with the metal roof complementing the clean lines of the home. Project specifications included a 25-year warranty on the metal and a total project cost of $65,000. The image depicts a light gray metal roof with vertical striations on a modern farmhouse, showcasing a visually striking and well-integrated design.

Project 2: The Mountain Retreat

This mountain retreat, built on a steep hillside, required a roofing solution that was both aesthetically pleasing and structurally sound. The striated design was chosen to enhance the rustic appeal of the property. A horizontal striation pattern, with varying widths, was employed. This pattern was chosen to simulate the texture of natural stone while ensuring proper water drainage. The aesthetic impact was a blend of rustic charm and modern sophistication. The project specifications included a 30-year warranty on the metal, with an emphasis on wind resistance. The total project cost was $72,000. The image portrays a dark gray metal roof with horizontal striations, strategically placed on a mountain retreat, showcasing a blend of rustic and modern aesthetics.

Project 3: The Commercial Building

This case study focuses on a modern commercial building. The goal was to create a contemporary and durable roof with a unique visual appeal. A complex, wave-like striation pattern was selected, incorporating varying depths and widths. This pattern provided an element of visual intrigue while maintaining effective water drainage. The aesthetic impact was one of dynamism and modernity, with the striated roof standing out against the surrounding landscape. The project specifications included a 50-year warranty, with a detailed analysis of wind loads and snow accumulation. The project cost was $125,000. The image presents a light gray metal roof with a wave-like striation pattern, reflecting the modern architectural style of the commercial building, displaying the complex design.

Project Specifications and Costs

| Project | Striation Pattern | Aesthetic Impact | Project Cost |

|---|---|---|---|

| Modern Farmhouse | Vertical, offset lines | Modern elegance | $65,000 |

| Mountain Retreat | Horizontal, varying widths | Rustic charm, modern sophistication | $72,000 |

| Commercial Building | Complex, wave-like | Dynamism, modernity | $125,000 |

Last Recap

In conclusion, striated standing seam metal roofs represent a compelling roofing option, balancing visual appeal with exceptional performance. Their durability, energy efficiency, and potential cost-effectiveness make them a suitable choice for a wide range of architectural styles and climate zones. Proper installation and maintenance, coupled with a thoughtful design approach, are key to maximizing the long-term benefits and aesthetic impact of this unique roofing solution.